VVD (VR 154-21) #8 w/motor AIR 200 L2 45 kW 3000 rpm high-pressure centrifugal fan for general industrial applications, manufactured according to scheme No. 5 with a V-belt drive and made of carbon steel.

VVD (VR 154-21) #8 w/motor AIR 200 L2 45 kW 3000 rpm high-pressure centrifugal fan for general industrial applications, manufactured according to scheme No. 5 with a V-belt drive and made of carbon steel.

Centrifugal (radial) high-pressure fan of the VVD (VR 154-21) #8 w/motor AIR 200 L2 45 kW 3000 rpm series, made of carbon steel. This fan is designed for moving air and other gas mixtures, and can operate for both suction and discharge in the temperature range from -16 to +40°C. The dust content in the medium should not exceed 150 mg/m3. High-pressure fans of the VVD (VR 154-21) #8 w/motor AIR 200 L2 45 kW 3000 rpm series are used in regions with moderate climate (U).

General information about VVD (VR 154-21) #8 w/motor AIR 200 L2 45 kW 3000 rpm:

Application area of high-pressure centrifugal fans VVD:

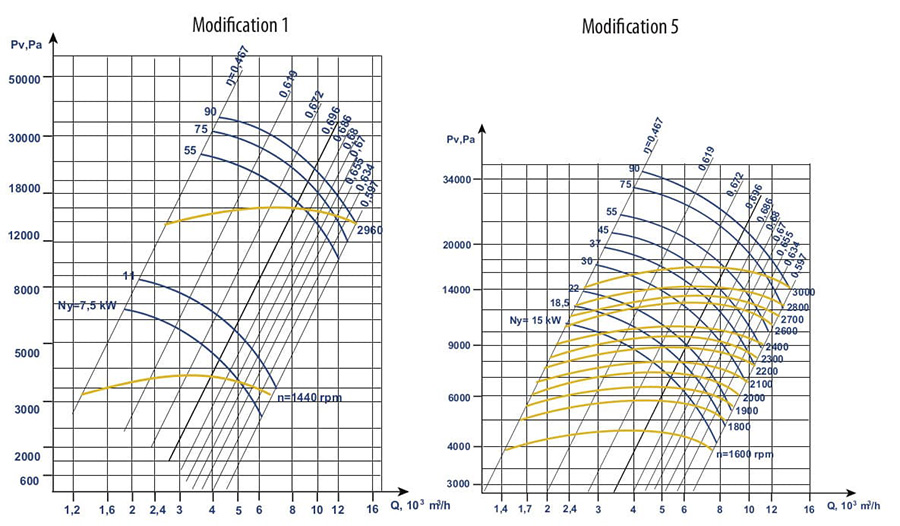

Manufacturing options for centrifugal fans VVD (VR 154-21) #8 w/motor AIR 200 L2 45 kW 3000 rpm:

Design and principle of operation of the VVD (VR 154-21) #8 w/motor AIR 200 L2 45 kW 3000 rpm fan:

Air movement is achieved by transferring rotational energy from the impeller of the fan. The overall design is an impeller mounted on a drive shaft (motor shaft or shaft of an intermediate transmission support), which is installed in the housing; the housing is mounted on a frame base; the entire structure is welded; a collector with a flange is located at the fan outlet.

The VVD (VR 154-21) #8 w/motor AIR 200 L2 45 kW 3000 rpm fan consists of the following main components:

Impeller of the VVD (VR 154-21) #8 w/motor AIR 200 L2 45 kW 3000 rpm fan:

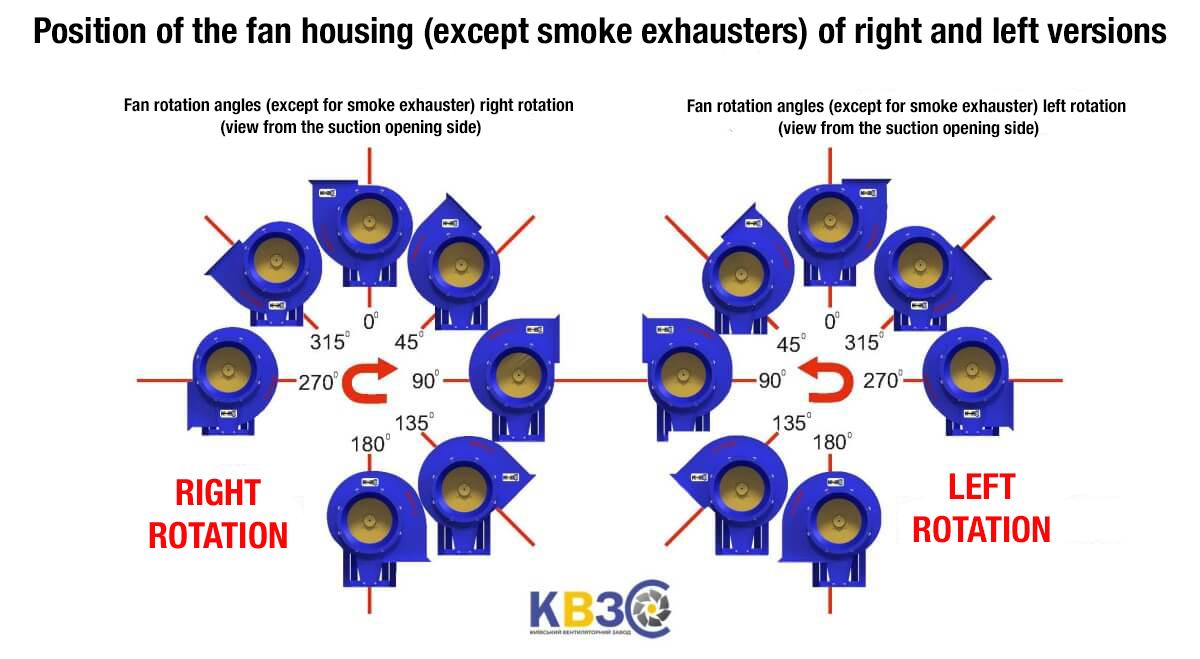

The impeller has a turbine-type design, with 12 blades. The blades are welded to the front and rear discs. The rear disc is attached to the hub by press fitting. Disc and blade material is sheet steel, the hub is made of gray cast iron. The purpose of the impeller is to create a vacuum in the suction zone and excess pressure in the discharge zone. The impeller can be of right or left rotation.

Spiral housing of the high-pressure fan VVD (VR 154-21) #8 w/motor AIR 200 L2 45 kW 3000 rpm:

The spiral housing is welded from sheet and structural steel. The spiral housing can be right or left rotation. The surfaces of the impeller and the spiral housing, which are in contact with the working medium, form the flow cavity. The housing is designed to form suction and discharge flows.

Electric motor AIR 200 L2 - general industrial asynchronous three-phase motor with a squirrel-cage rotor, designed to operate from a power network with alternating current frequency 50 Hz and voltage 220/380 V. The Electric motor AIR 200 L2 motor has a nominal speed of 3000 rpm. Frame size (center height): 200 mm; shaft diameter: 55 mm; power in kW: 45.0; climate version: UZ; IP: 54. By order, the Electric motor AIR 200 L2 motor 45.0 Power kW can be manufactured with a silumin alloy housing.

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.