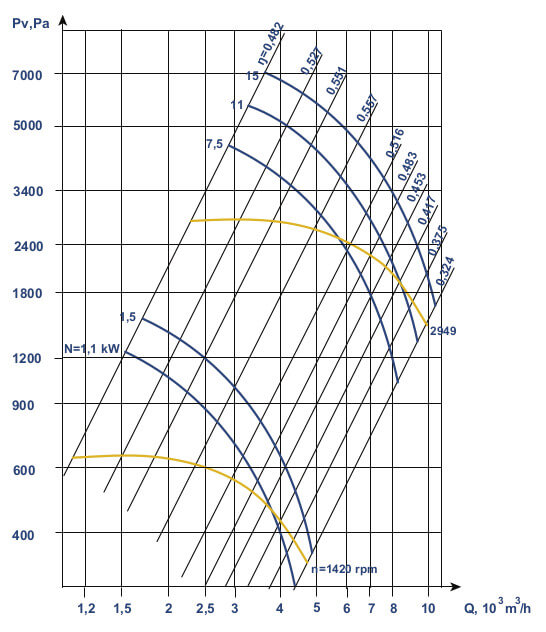

Dust centrifugal fan of the VCP 6-46 #4 series with an electric motor [el.name 15.0 Power kW 3000 Vol./Min, manufactured according to design scheme No. 5 with a V-belt drive

Dust centrifugal fan of the VCP 6-46 #4 series with an electric motor [el.name 15.0 Power kW 3000 Vol./Min, manufactured according to design scheme No. 5 with a V-belt drive

The centrifugal (radial) dust fan of the VCP 6-46 #4 series (VCP 115-52) with electric motor Electric motor AIR 160 S2 15.0 Power kW 3000 Vol./Min, designed according to layout No. 5 with belt drive, is made of carbon steel.

This fan is intended for conveying explosion-proof, non-abrasive dust-gas-air mixtures with air temperatures not exceeding 80 °C. The aggressiveness of the mixture toward ordinary-grade carbon steel should not exceed that of air. The mixture must not contain sticky substances or fibrous materials. The concentration of mechanical impurities in the conveyed medium is up to 1000000 mg/m3 (1 kg/m3). The fan VCP 6-46 #4 (VCP 115-52) is used for removing chips and metal dust from machines in sanitary-technical and industrial applications under stationary conditions.

The welded impeller consists of 8 radially arranged straight blades, a hub, and two disks.

The spiral housing is a one-piece structure. A cylindrical inlet nozzle with a flange is attached to the front wall. The outlet nozzle is welded to the housing. The gap between the inlet and impeller is adjustable.

The Electric motor AIR 160 S2 motor is a general-purpose three-phase asynchronous motor with a squirrel-cage rotor. It is designed for operation on an AC network with a frequency of 50 Hz and voltage of 220/380 V. Nominal rotation speed: 3000 rpm. Frame size (shaft height): 160 mm; shaft diameter: 38 mm; power: 15.0 kW; climatic version: UZ; IP rating: 54.

The fan is driven by the motor via a belt drive. The pulleys and belts are enclosed in a protective cover. The fan housing and motor are mounted on a shared welded frame made of channels and angles. The frame has mounting holes for installation on a foundation. The impeller and pulleys are keyed onto the shafts and axially secured with end lock washers and bolts. The dust-gas-air mixture enters through the inlet, is captured by the impeller, and discharged through the outlet via the spiral housing.

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.