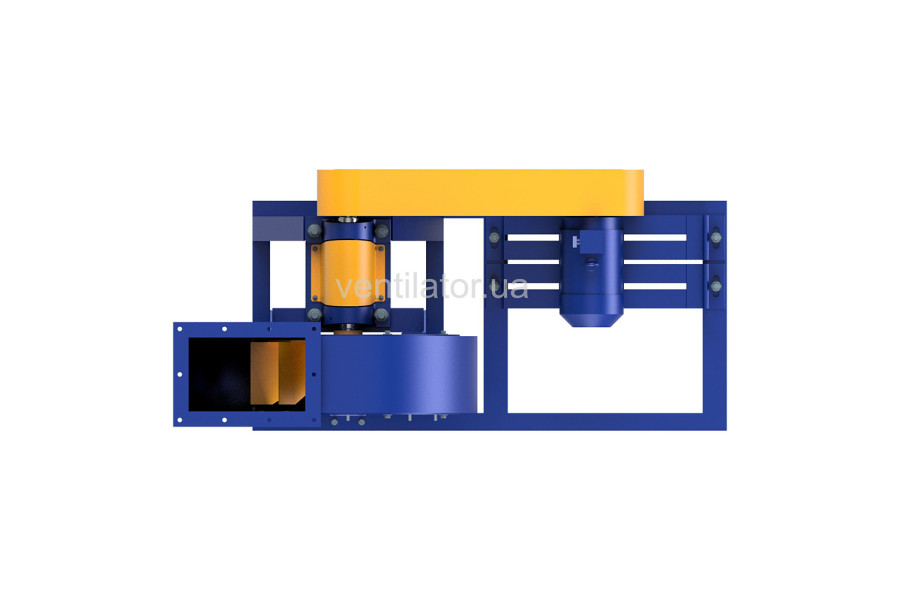

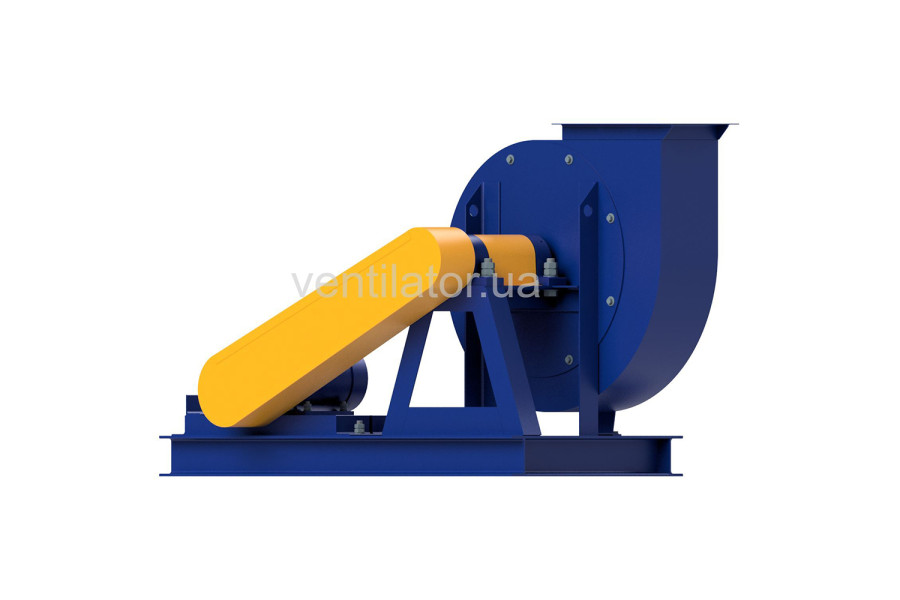

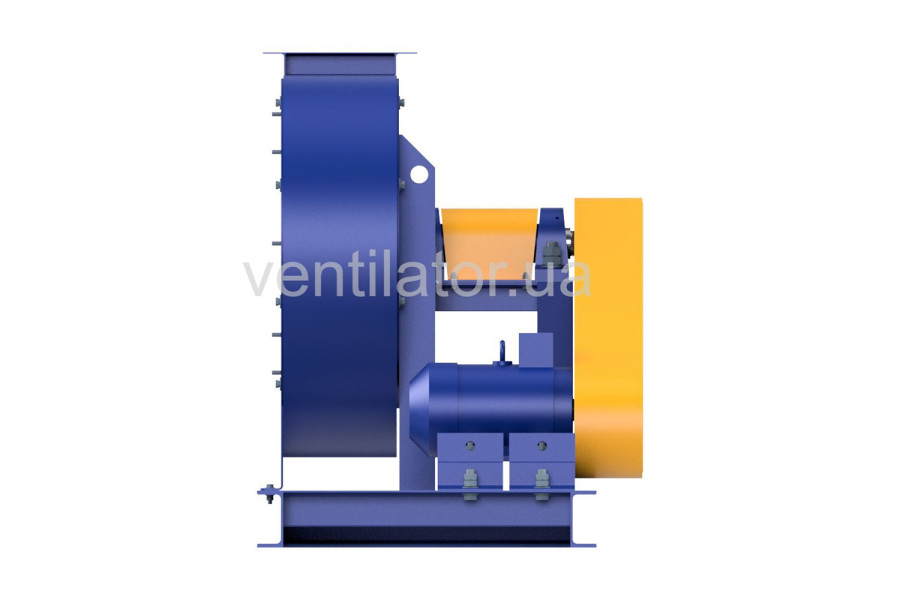

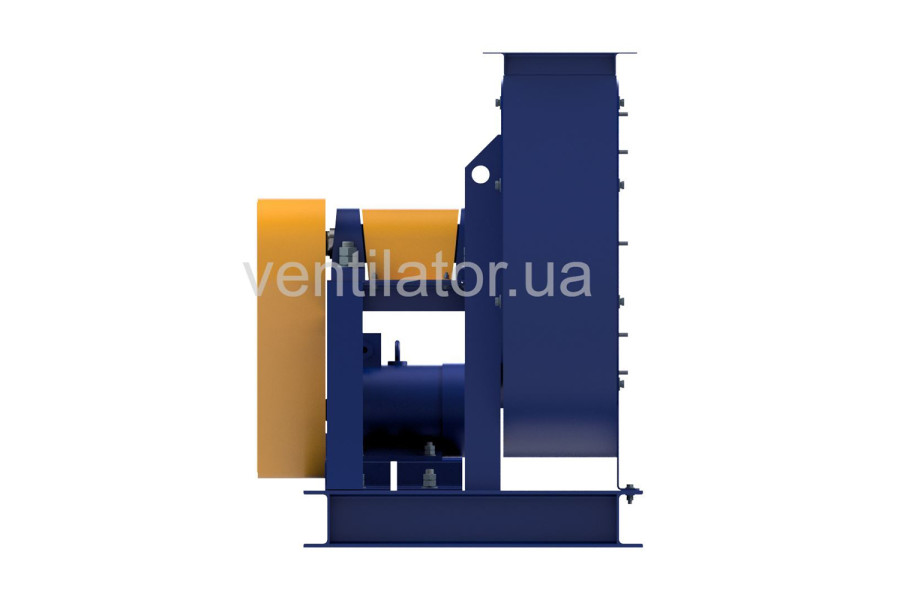

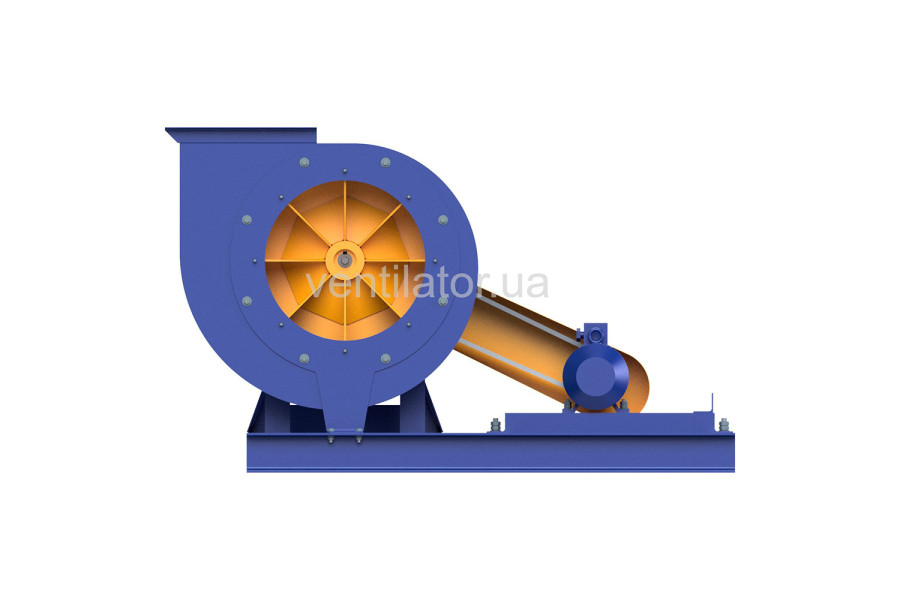

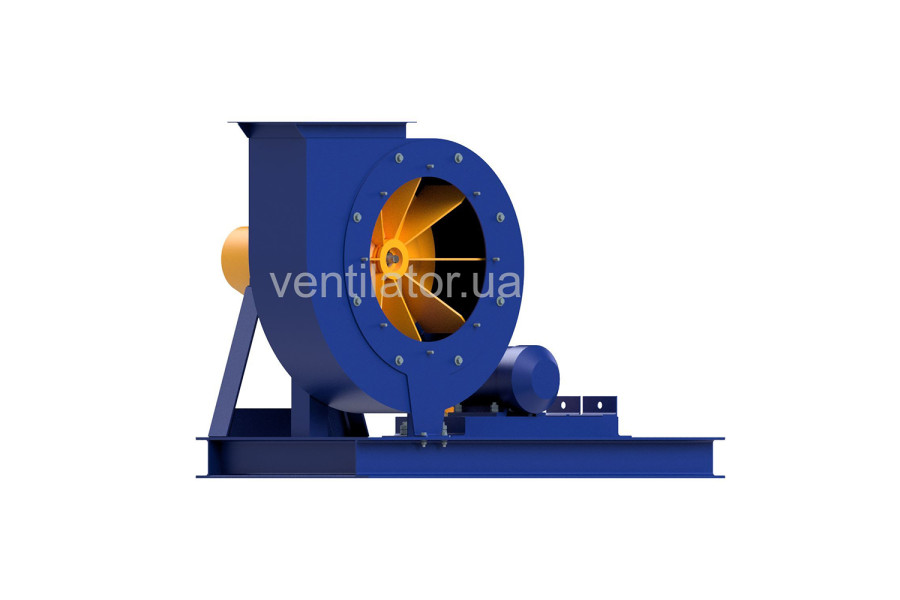

Fan of the VCP 5-45 #3,15 series, design No. 5, with belt drive and Electric motor AIR 80 B2 2.2 kW 3000 RPM.

VCP 5-45 #3.15 w/motor AIR 80 B2 2.2 kW 3000 rpm, execution 5

The centrifugal fan of the dust

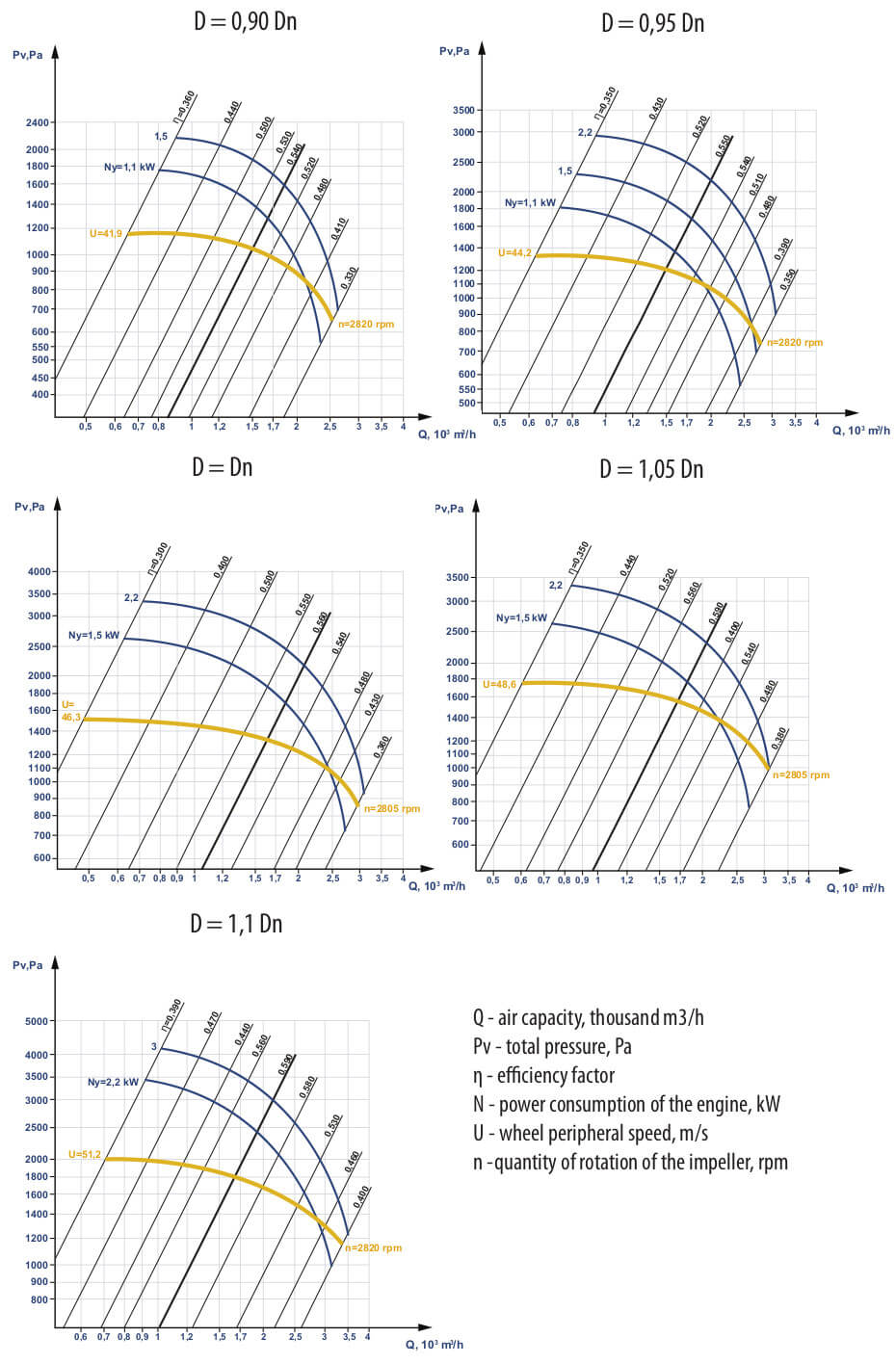

Centrifugal (radial) dust fan of the VCP 5-45 #3,15 series (VCP 110-43) with electric motor Electric motor AIR 80 B2 2.2 Power kW 3000 Vol./Min, manufactured according to design scheme No. 5 with a V-belt drive, made of carbon steel.

This fan is intended for conveying explosion-proof non-abrasive dust-air-gas mixtures with air temperature not exceeding 80 °C, whose aggressiveness towards ordinary carbon steel does not exceed that of air; not containing sticky substances or fibrous materials. The content of solid particles in the conveyed medium is up to 1000000 mg/m3 (1 kg/m3).

The dust fan VCP 5-45 #3,15 (VCP 110-43) is designed for extracting wood dust and chips from woodworking machines, metal dust and shavings from metalworking machines, as well as for sanitary and industrial applications under stationary conditions.

General Information about Dust Fans VCP 5-45 #3.15 w/motor AIR 80 B2 2.2 kW 3000 rpm (VCP 110-43):

- single-sided suction;

- rotatable spiral housing;

- radial straight blades;

- number of blades – 8 pcs;

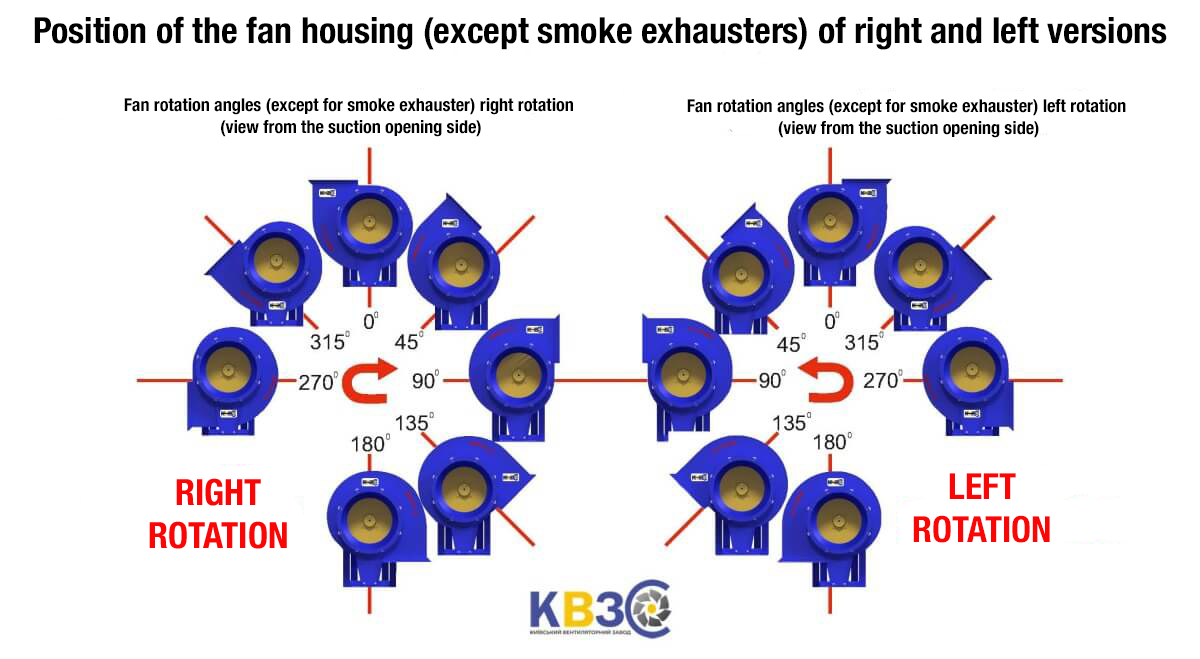

- rotation direction – right or left;

- design scheme: No. 5 – with V-belt drive;

- material: carbon steel;

Application Areas of Dust Fans VCP 5-45 #3.15 w/motor AIR 80 B2 2.2 kW 3000 rpm (VCP 110-43):

- in dust collection systems;

- in pneumatic conveying systems;

- for removal of wood dust and chips from woodworking machines;

- for removal of metal dust and shavings from metalworking machines;

- for other sanitary and industrial purposes.

Available Versions of Centrifugal Fans VCP 5-45 #3,15 (VCP 110-43):

- made of carbon steel;

- made of stainless steel;

- made of dissimilar metals.

Construction of the Dust Fan VCP 5-45 #3,15 (VCP 110-43), Main Assemblies and Operating Principle:

Housing (casing) VCP 5-45 #3,15

The spiral housing is a non-separable structure. A cylindrical inlet nozzle with a flange is attached to the front wall of the housing. The outlet nozzle is welded to the housing. The gap between the inlet nozzle and the impeller is adjustable.

Impeller of the Fan VCP 5-45 #3,15 (VCP 110-43)

The impeller is welded, consists of 8 radially positioned straight blades, a hub, and two sprockets.

Electric motor AIR 80 B2 2.2 Power kW 3000 Vol./Min

The motor Electric motor AIR 80 B2 is a general-purpose three-phase asynchronous motor with a squirrel-cage rotor, designed for operation from an AC mains at 50 Hz and 220/380 V. The nominal rotation speed of the motor Electric motor AIR 80 B2 is 3000 rpm. Frame size (shaft height): 80 mm; shaft diameter: 22 mm; power: 2.2 kW; climate version: UZ; IP rating: 54.

The direction of fan rotation is determined from the inlet side: clockwise – right rotation; counterclockwise – left rotation. The fan operates by transferring rotational energy from the impeller to the air. As the impeller spins, the air mixture entering between the blades moves outward due to centrifugal force and is discharged through the outlet.

Housing Positions of Radial Fans with Right (R) and Left (L) Rotation, Viewed from the Inlet Side:

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.

No questions about this product, be the first and ask your question.