Low pressure centrifugal fan VC 4-75 #6.3 w/motor AIR 90 L6 1.5 kW 1000 rpm, execution 1

- VC 4-75 #6.3 w/motor AIR 100 L4 4 kW 1500 rpm 30 637₴

- VC 4-75 #6.3 w/motor AIR 100 L6 2.2 kW 1000 rpm 30 260₴

- VC 4-75 #6.3 w/motor AIR 100 S4 3 kW 1500 rpm 30 666₴

- VC 4-75 #6.3 w/motor AIR 112 M4 5.5 kW 1500 rpm 34 770₴

- VC 4-75 #6.3 w/motor AIR 112 MA6 3 kW 1000 rpm 34 059₴

- VC 4-75 #6.3 w/motor AIR 132 M4 11 kW 1500 rpm 43 615₴

- VC 4-75 #6.3 w/motor AIR 132 S4 7.5 kW 1500 rpm 40 845₴

- VC 4-75 #6.3 w/motor AIR 80 B6 1.1 kW 1000 rpm 26 490₴

Series VC 4-75 #6,3 low-pressure centrifugal fan (VR 88-72.1-5.5, VR 80-75-5) with electric motor Electric motor AIR 90 L6 1.5 Power kW 1000 Vol./Min, manufactured from dissimilar materials for explosive atmospheres.

Intended Application:

This fan is designed for ventilation or air-conditioning systems handling gas–steam–air explosive mixtures of the 1st and 2nd categories (groups T1, T2, T3) according to the “Rules for Electrical Installations” (PVE), which do not cause accelerated corrosion of the flow-path materials. These mixtures must not exceed a temperature of 80 °C, and the content of fibrous materials, sticky substances, dust, and other solid impurities must not exceed 100 mg/m³ under moderate (U) climate (placement category 3) and tropical (T) climate (placement category 2). Ambient temperature is permitted from −40 °C to +40 °C (+40 °C when equipped with tropical-design electric motors).

Housing and Impeller Blade Material:

The housing and impeller blades of these explosion-proof fans are made from material pairs (steel–brass or steel–aluminum) that form a non-sparking combination under frictional conditions.

Configuration and Modular Components (available separately):

- Fan assembly VC 4-75 #6,3 (VR 88-72.1-5.5, VR 80-75-5) without electric motor

- Impeller wheel of fan VC 4-75 #6,3 (VR 88-72.1-5.5)

- Fan scroll casing VC 4-75 #6,3 (VR 80-75-5)

- Electric motor AIR 90 L6

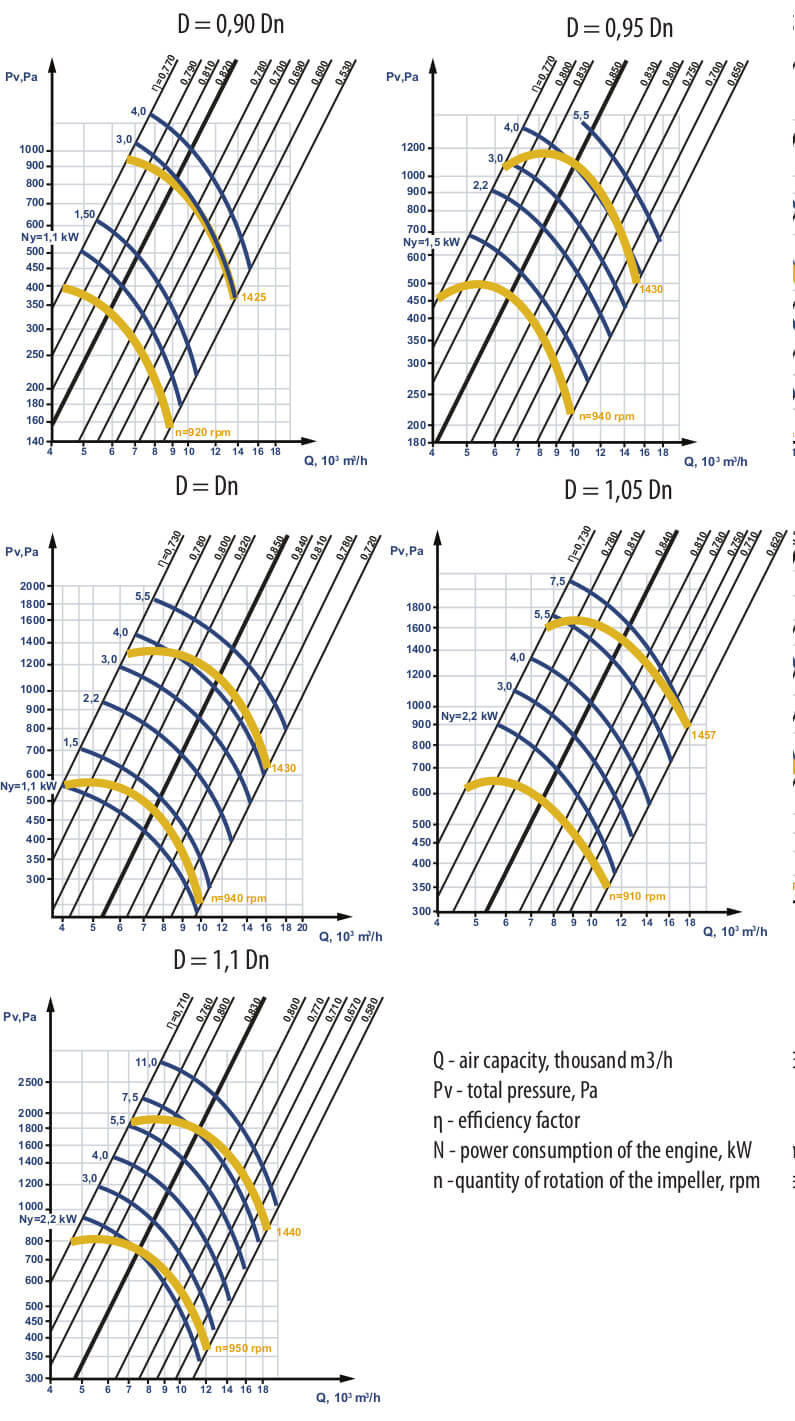

General Characteristics of Series VC 4-75 #6,3 Centrifugal Fans with Electric motor AIR 90 L6 1.5 Power kW 1000 Vol./Min, Manufactured from Dissimilar Metals:

- Low pressure

- Single-sided suction

- Backward-curved blades

- Number of blades: 12

- Direction of rotation: right and left

- Execution scheme № 5 with V-belt drive

- Construction material: dissimilar metals

Applications of Series VC 4-75 #6.3 w/motor AIR 90 L6 1.5 kW 1000 rpm Fans (VR 88-72.1-5.5, VR 80-75-5):

- Air-conditioning systems

- Ventilation systems

- Air-heating systems

- Other sanitary and industrial purposes

Operating Conditions:

Series VC 4-75 #6.3 w/motor AIR 90 L6 1.5 kW 1000 rpm centrifugal fans operate under moderate climate conditions at ambient temperatures from −40 °C to +40 °C. The temperature of the conveyed medium must not exceed 80 °C.

Principle of Operation:

Air, by means of energy imparted by the impeller blades, enters the fan under centrifugal force at a 90° angle and is directed radially into the scroll-shaped casing. Within the casing, the pressurized air follows a spiral path and is discharged through the fan outlet.

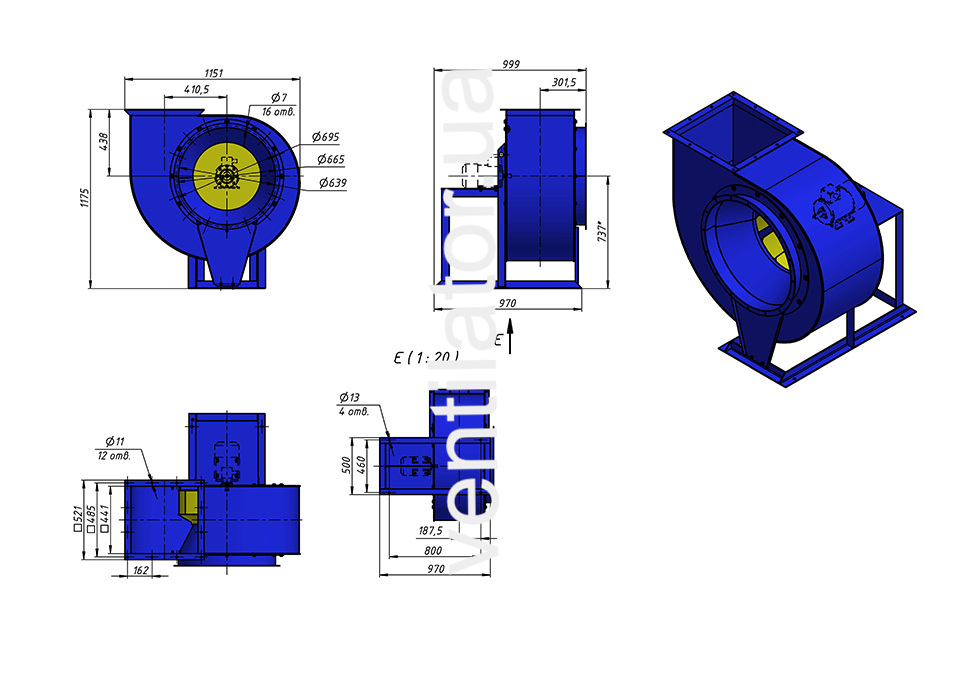

Delivery Set of Series VC 4-75 #6,3 Fans Made of Dissimilar Metals:

- Scroll-shaped casing

- Impeller wheel (front and rear discs, 12 sheet blades, and hub)

- Support frame (welded stand with hole for mounting on vibration isolators or foundation)

- Collector (conical, attached to the inlet nozzle; overlap between collector and impeller front disc is adjusted by axial movement within the inlet nozzle)

- Electric motor Electric motor AIR 90 L6 1.5 Power kW 1000 Vol./Min

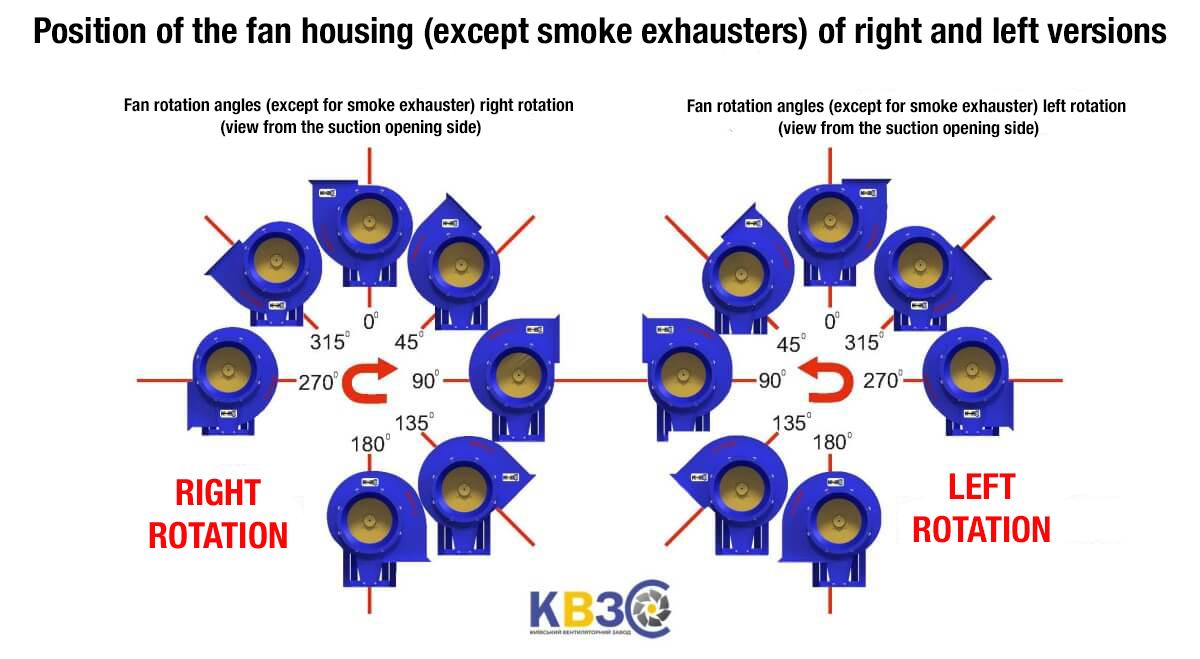

Position of Radial Fan Housings for Right (PR) and Left (LIV) Rotation, Viewed from the Suction Side:

- Right rotation

- Left rotation

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.