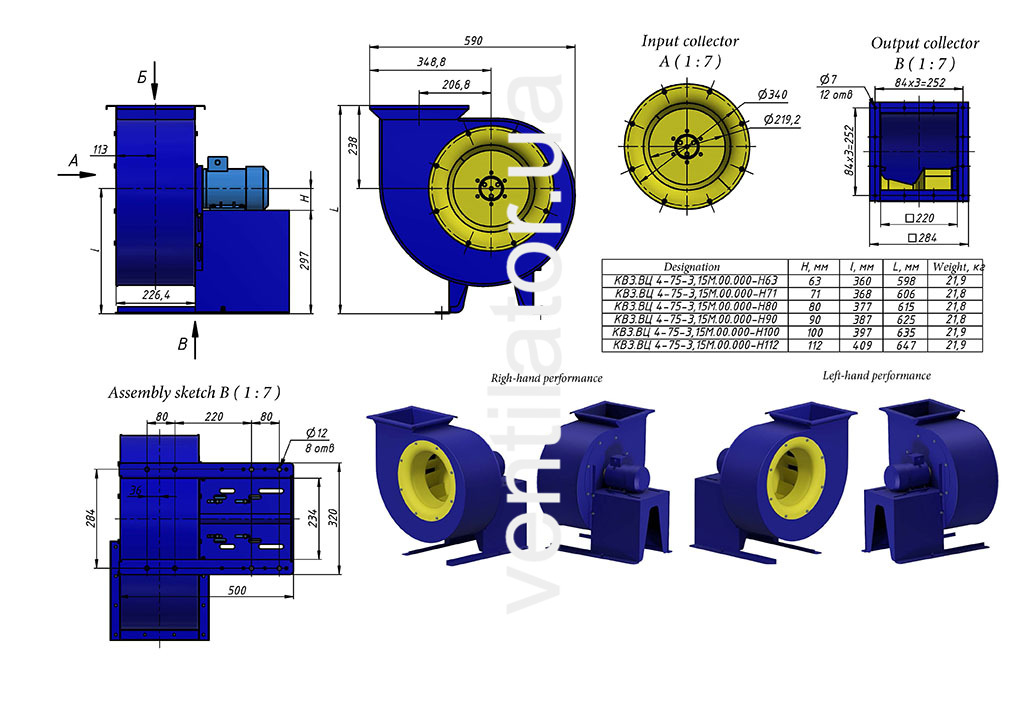

Low-pressure centrifugal fan VC 4-75 VZ #3.15 w/motor 4VR 63 A4 0.25 kW 1500 rpm manufactured according to design scheme #1. Equipped with brass overlays in friction zones for explosion protection.

Low-pressure centrifugal fan VC 4-75 VZ #3.15 w/motor 4VR 63 A4 0.25 kW 1500 rpm manufactured according to design scheme #1. Equipped with brass overlays in friction zones for explosion protection.

Low-pressure centrifugal fan of the VC 4-75 VZ #3.15 w/motor 4VR 63 A4 0.25 kW 1500 rpm series (VR 88-72.1-5.5, VR 80-75-5) for general industrial use, made of carbon steel.

This fan is intended for ventilation or air conditioning systems and other gas mixtures, the aggressiveness of which towards carbon steel does not exceed that of air with a temperature up to 80°C. The transported medium should not contain fibrous materials, sticky substances, dust, or other solid impurities in an amount not exceeding 100 mg/m3, under moderate (U) climate conditions (placement category 3) and tropical (T) climate (placement category 2).

The centrifugal fan VC 4-75 VZ #3.15 w/motor 4VR 63 A4 0.25 kW 1500 rpm is designed for moving air and other gas mixtures whose aggressiveness to carbon steel does not exceed that of air, and which do not contain sticky substances, fibrous materials, or dust and other solid impurities in an amount not exceeding 100 mg/m3.

The centrifugal fan VC 4-75 VZ #3.15 w/motor 4VR 63 A4 0.25 kW 1500 rpm (VR 88-72.1-5.5, VR 80-75-5) is operated under moderate climate conditions, at ambient temperatures from -40°C to +40°C. The temperature of the transported medium must not exceed 80 °C.

The air, by receiving energy from the impeller blades, enters the fan under centrifugal force at a 90-degree angle and moves radially into the spiral casing; in the casing, moving along the spiral-shaped housing under pressure, it is directed through the fan outlet.

The impeller consists of a front and rear disk, 12 sheet blades, and a hub. The base frame of the fan is welded. The base has a hole for installation on vibration isolators or a foundation. The electric motor and casing are mounted on the base. The conical collector, for supplying air to the impeller, is attached to the inlet nozzle. The overlap between the collector and the front disk of the impeller is adjusted by axially moving the collector in the inlet nozzle.

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.