Average-pressure centrifugal fan series VC 10-28 (BP 200-28) #2.5 w/motor AIR 71 B2 1.1 kW 3000 rpm, arranged according to the scheme of execution #1 the impeller on the motor shaft is made of carbon steel.

Average-pressure centrifugal fan series VC 10-28 (BP 200-28) #2.5 w/motor AIR 71 B2 1.1 kW 3000 rpm, arranged according to the scheme of execution #1 the impeller on the motor shaft is made of carbon steel.

Centrifugal (radial) medium pressure fan of the VC 10-28 (BP 200-28) #2.5 w/motor AIR 71 B2 1.1 kW 3000 rpm series, manufactured according to design scheme No. 1 with the impeller mounted on the motor shaft, made of carbon steel.

This fan is designed for moving air and other gas mixtures whose aggressiveness towards ordinary quality carbon steel does not exceed that of air, with a temperature up to +80°C, not containing sticky substances, fibrous materials, as well as dust and other solid impurities not exceeding 100 mg/m3, for use in moderate (U) climate, placement category 3, and tropical (T) climate, placement category 2.

When providing protection for motors against atmospheric influences, VC 10-28 (BP 200-28) #2.5 w/motor AIR 71 B2 1.1 kW 3000 rpm (VR 196-32.1) fans can be used. The ambient temperature range is from minus 40°C to +40°C (+45°C for fans of tropical design).

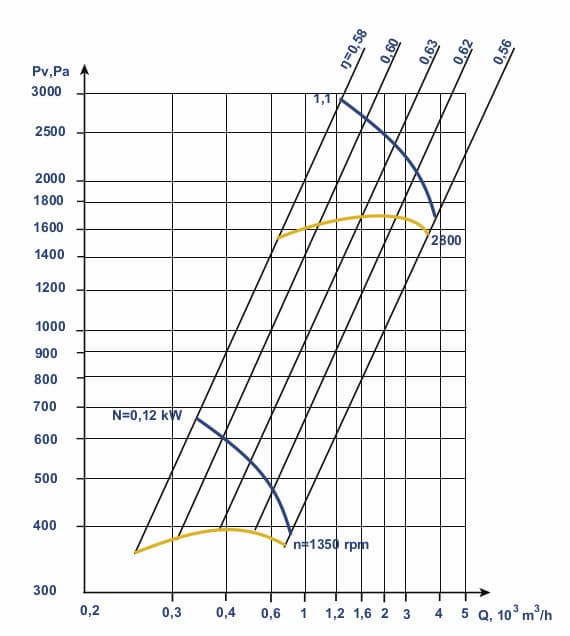

General information about medium pressure centrifugal fans VC 10-28 (BP 200-28) #2.5 w/motor AIR 71 B2 1.1 kW 3000 rpm (VR 196-32.1):

Application of medium pressure centrifugal fans VC 10-28 (BP 200-28) #2.5 w/motor AIR 71 B2 1.1 kW 3000 rpm (VR 196-32.1):

Medium pressure centrifugal fans VC 10-28 (BP 200-28) #2.5 w/motor AIR 71 B2 1.1 kW 3000 rpm (VR 196-32.1) are used in stationary air conditioning and ventilation systems of industrial, public, and residential buildings, as well as for other sanitary and industrial purposes.

Manufacturing options for centrifugal fans VC 10-28 (BP 200-28) #2.5 w/motor AIR 71 B2 1.1 kW 3000 rpm:

Design and principle of operation of medium pressure centrifugal fans of the VC 10-28 (BP 200-28) #2.5 w/motor AIR 71 B2 1.1 kW 3000 rpm series:

Air movement is achieved by transferring rotational energy to the air by the fan impeller.

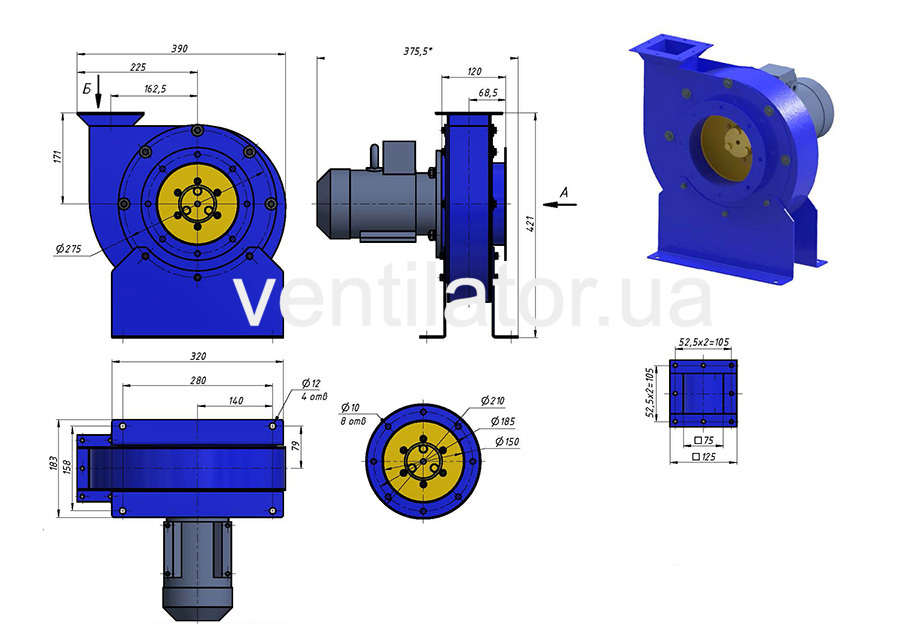

The VC 10-28 (BP 200-28) #2.5 w/motor AIR 71 B2 1.1 kW 3000 rpm fan consists of the following main components:

Impeller of the fan VC 10-28 (VR 200-28) #2,5 (VR 196-32.1)

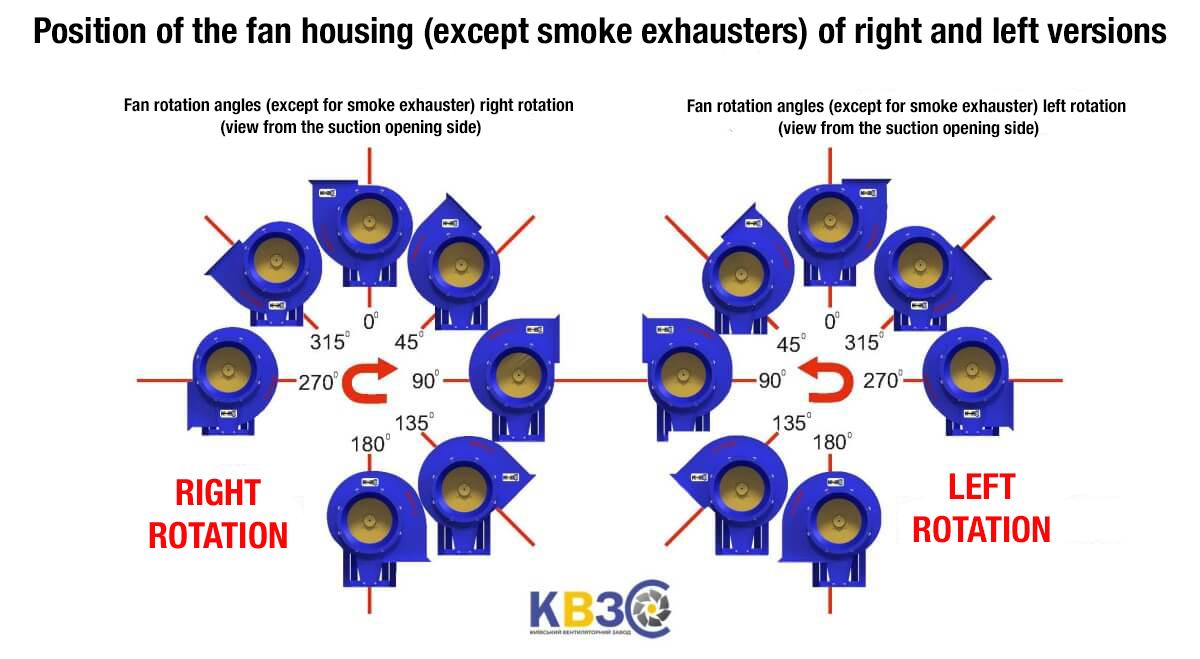

The impeller design is of turbine type, with 48 blades. The blades are welded to the front and rear discs. The rear disc is attached to the hub by press-fitting. The discs and blades are made of sheet steel, the hub is made of gray cast iron. The purpose of the impeller is to create a vacuum in the suction zone and excess pressure in the discharge zone. The impeller can be of right or left rotation.

Spiral housing of the medium pressure fan VC 10-28 (VR 200-28) #2,5 (VR 196-32.1)

The spiral housing is welded from sheet and shaped steel. The spiral housing can be of left or right rotation. The surfaces of the impeller and the spiral housing in contact with the medium form the flow cavity. The purpose of the housing is to form the suction and discharge flows.

Inlet pipe:

The inlet pipe is made of sheet steel and serves to draw in and direct the air to the impeller. The round-section inlet pipe is equipped with a flange for connection to the suction air duct.

Bearing assembly (rotating part):

The rotating part of the fan is designed to set the impeller in rotational motion. The bearing assembly consists of a shaft mounted on two bearing supports in a cast iron housing. The impeller is attached to one end of the shaft, and the driven pulley to the other. To prevent dust from entering the bearing housing, sealing rings are provided in its covers. The bearing housing has a cavity for lubrication.

Bedplate:

The bedplate is used for mounting the bearing housing and spiral housing. It has a box-shaped design and is made of sheet and shaped steel.

There are holes in the lower part of the bedplate for fastening it to the frame.

Frame:

The fan frame is welded from shaped steel and serves for installation of all the fan assemblies. Holes are provided in the lower surface of the frame for mounting the fan to the foundation.

Position of the housings of right-hand (RH) and left-hand (LH) radial fans, view from the suction side:

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.