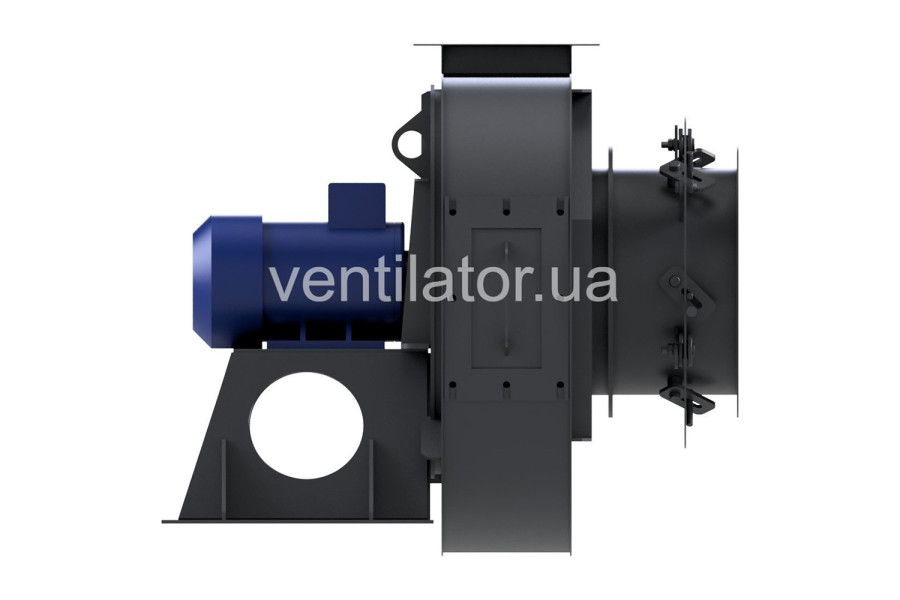

The DN #5 w/motor AIR 100 L2 5.5 kW 3000 rpm series induced draft fan for general industrial use is manufactured according to design scheme No. 1, with the impeller mounted directly on the motor shaft.

The DN #5 w/motor AIR 100 L2 5.5 kW 3000 rpm series induced draft fan for general industrial use is manufactured according to design scheme No. 1, with the impeller mounted directly on the motor shaft.

DN #5 w/motor AIR 100 L2 5.5 kW 3000 rpm, manufactured from high-quality carbon steel, is equipped with a backward-curved blade impeller—a modern engineering solution for industrial smoke exhausters. This design provides high efficiency (up to 80–85%), low noise levels, and stable operation even with changing network resistance. Compared to radial blades, backward-curved blades help reduce energy consumption while maintaining required flow and pressure, and they extend the unit’s service life due to reduced wear.

Advantages of smoke exhausters with backward-curved blades:

The smoke exhauster is designed for removal of combustion gases and non-explosive dust-laden air mixtures from furnace chambers of boiler units. It is used for solid-fuel boilers with steam capacities from 2.5 to 25 tons per hour, as well as for gas and oil-fired boilers of similar capacity. The maximum temperature of handled gases is up to +200°C. DN #5 series smoke exhausters can be used both individually and in parallel operation and are equipped with an ash collection system with a cleaning efficiency of at least 90%.

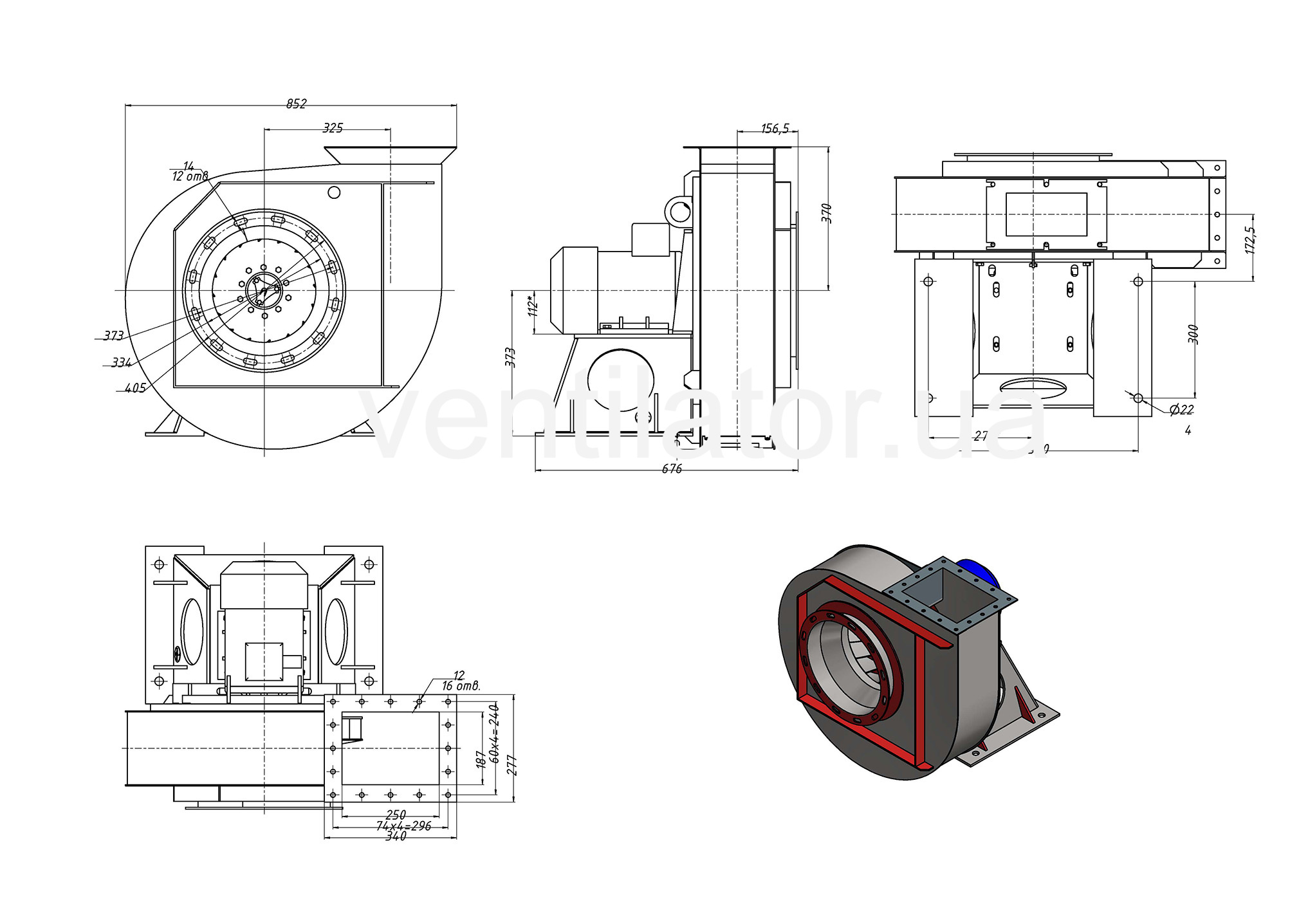

Structurally, the DN #5 w/motor AIR 100 L2 5.5 kW 3000 rpm smoke exhauster consists of the following units (can be supplied separately):

The DN #5 w/motor AIR 100 L2 5.5 kW 3000 rpm smoke exhauster housing is welded and made of durable carbon steel. The impeller (cantilever-mounted) is backward-curved, ensuring streamlined gas flow. For long-lasting operation, thickened scroll walls and hardfacing on the blades are used. Standard configuration includes a three-phase AIR electric motor (380V, 50Hz).

The smoke exhauster can be manufactured with right- or left-hand rotation. The scroll housing can be rotated from 0 to 270°.

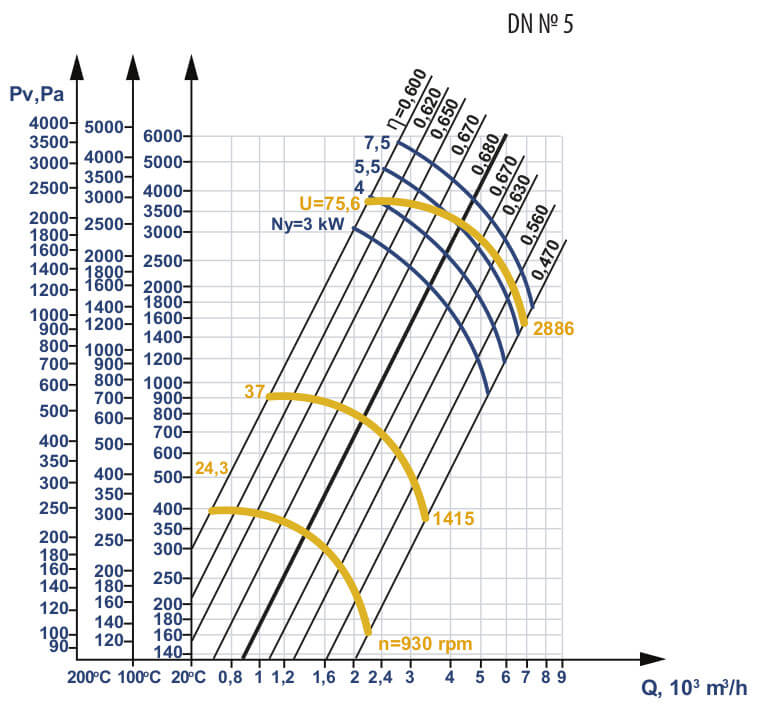

General specifications of DN #5 w/motor AIR 100 L2 5.5 kW 3000 rpm smoke exhausters:

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.