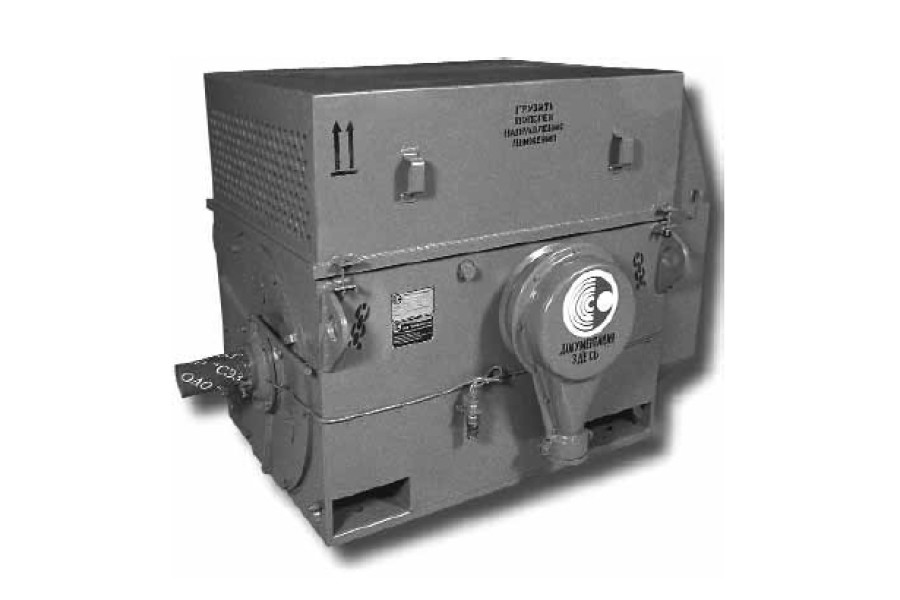

General information about the asynchronous electric motor DAZO4-85/37-4U1

Three-phase asynchronous squirrel-cage electric motors of the ДAЗО4 series are designed to drive mechanisms that do not require speed control (pumps, fans, smoke exhausters, etc.). The motors are intended to operate on an AC network with a frequency of 50 Hz and a voltage of 10000 V.

Characteristics of the asynchronous electric motor DAZO4-85/37-4U1

Climatic version - U1.

Nominal duty cycle - long S1.

Design version of the motors - IM1001.

Cooling method of the motors - ICA01A61.

Degree of protection - IP 54, terminal boxes - IP55, external fan - IP21.

Operation of the asynchronous electric motor DAZO4-85/37-4U1

The motors can be started directly, ensuring starting at both nominal network voltage and when the network voltage drops to 0.8 U nom during startup. The motors allow two consecutive starts from a cold state or one start from a hot state. The interval between subsequent starts must be at least three hours; the number of starts must not exceed 10,000 over the service life and 500 starts per year.

Design of the asynchronous electric motor DAZO4-85/37-4U1

The motors have rolling bearings with grease lubrication. Bearing temperature is monitored by resistance temperature detectors. Connection of the motors to the drive mechanism is carried out by flexible couplings. The stator winding insulation materials have a heat-resistance class of at least “B”. The stator winding insulation is of the thermosetting “Monolit-2” type. The stator winding has six leads fixed on four insulators in the terminal box. The winding connection is star. Stator winding and core temperature monitoring is performed by six temperature detectors embedded in the stator slots. The motors allow both clockwise and counterclockwise rotation. Reversing the direction of rotation is performed only from a stationary state. The motors can be equipped with SKF or FAG bearings.