Exhauster series 180 with electric motor Electric motor AIR 100 L8 1.5 Power kW 750 Vol./Min for general industrial use. Fan working point: AIR, A m3/hour at a pressure of 2000 Pa.

D #5 w/motor AIR 100 L8 1.5 kW 750 rpm, execution 1

Exhauster

Flue Gas Fan of the 180 Series with electric motor Electric motor AIR 100 L8 1.5 Power kW 750 Vol./Min, made of carbon steel.

This fan is designed for removing gases from boiler units operating on gas and fuel oil. The temperature of the transported gases must not exceed 200–250 °C. Minimum scroll temperature: -30 °C.

180 flue gas fans are also used in industrial facilities for sanitary and technical purposes, including metallurgical plants, thermal power stations, etc.

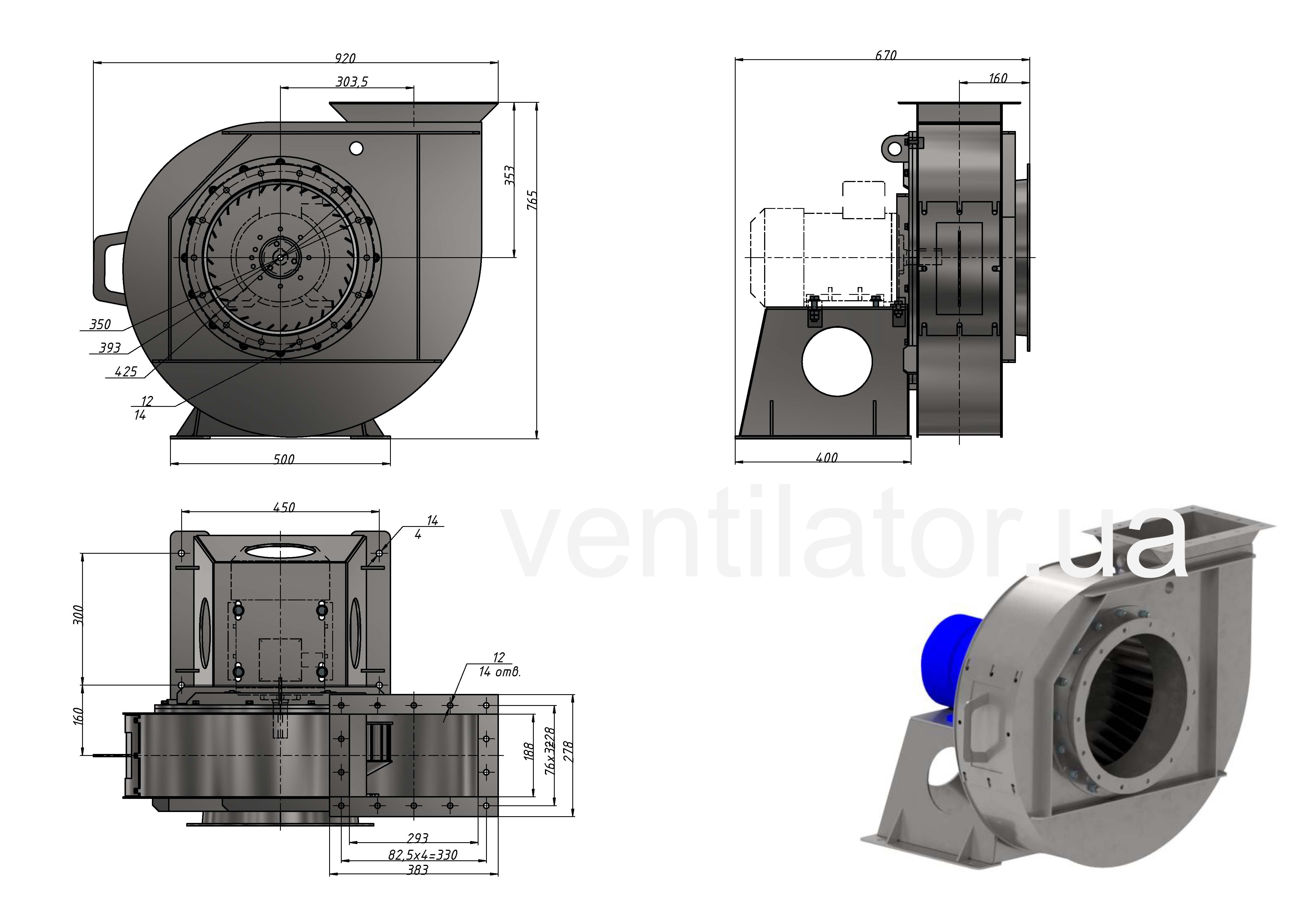

The 180 flue gas fan consists of the following components (available separately):

- spiral scroll housing 180

- impeller 180

- fan base frame 180

- fan collector 180

- electric motor Electric motor AIR 100 L8 1.5 Power kW 750 Vol./Min for fan 180

General Information about D #5 w/motor AIR 100 L8 1.5 kW 750 rpm:

- Single-side suction

- Adjustable spiral scroll housing

- Forward-curved blades

- Number of blades: 32

- Rotation: right-hand or left-hand (viewed from motor side)

Application of D #5 w/motor AIR 100 L8 1.5 kW 750 rpm Flue Gas Fans:

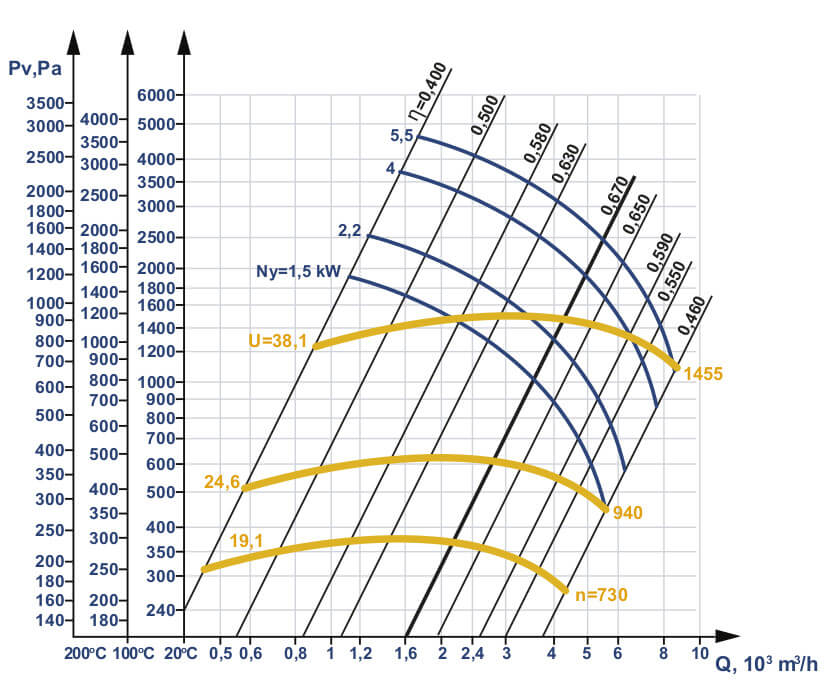

D #5 w/motor AIR 100 L8 1.5 kW 750 rpm is designed for use in thermal power as an exhaust fan for steam and hot water boilers with balanced draft (up to 25 t/h or 20 MW), running on various fuels. Fans must be equipped with an efficient ash collection system. They are suitable for long-term operation both indoors and outdoors in temperate climates. Startup is permitted if the scroll temperature is not lower than -30 °C. Maximum gas inlet temperature must not exceed +250 °C.

Use in gas/fuel oil boilers and industrial process units across various sectors is permitted, including power plants, metallurgical enterprises, chemical industry, air purification systems, and dust collectors.

D #5 w/motor AIR 100 L8 1.5 kW 750 rpm Flue Gas Fans Are Used In:

- thermal power

- gas and oil-fired boilers

- steam and hot water boilers

- other sanitary and industrial applications

Operating Principle of D #5 w/motor AIR 100 L8 1.5 kW 750 rpm:

The fan works by transferring rotational energy from the impeller (mounted on the motor shaft) to the air. The air mixture enters through the collector, passes between the impeller blades, and moves to the periphery due to centrifugal force. Flue gases mixed with air are redirected 90° radially and discharged through the scroll housing.

Operating Conditions of D #5 w/motor AIR 100 L8 1.5 kW 750 rpm:

- Carbon steel housing: gas temperature must not exceed +250 °C

- Startup allowed at scroll temperature no lower than -30 °C

- Ambient temperature: -40 °C to +40 °C

- RMS vibration velocity ≤ 2 mm/s at installation site

- Dust content ≤ 2 g/m3

Scroll Position of Right-Hand (R) and Left-Hand (L) Rotation Fans, View from Suction Side:

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.

No questions about this product, be the first and ask your question.