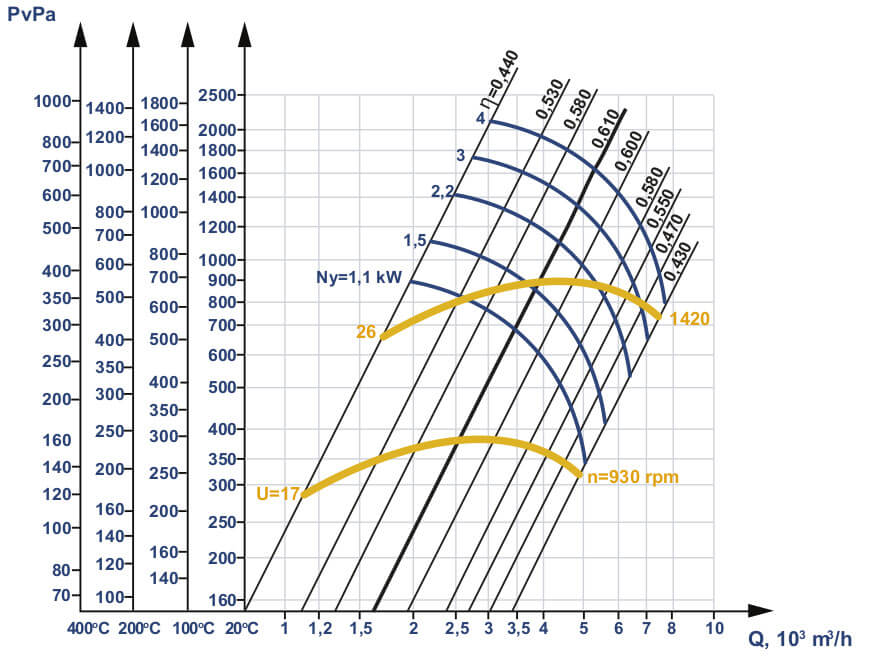

Exhauster series D 3,5 with electric motor Electric motor AIR 100 L4 4.0 Power kW 1500 Vol./Min for general industrial use, made according to the scheme of execution #3 of carbon steel. Fan working point: 3910 m3/hour at a pressure of 878 Pa.

D 3.5 w/motor AIR 100 L4 4 kW 1500 rpm, execution 3

Exhauster

Smoke exhauster series D 3,5 with electric motor Electric motor AIR 100 L4 4.0 Power kW 1500 Vol./Min, made of carbon steel.

This fan is designed for removing flue gases from small-capacity boiler units with output up to 1 t/h of steam, fueled by gas or fuel oil. The temperature of conveyed gases must not exceed 200 °C for models with ST3 grade steel impellers and 400 °C for those with heat-resistant 09G2S steel impellers.

Ambient temperature range: –40 °C to +40 °C.

The D 3.5M models are also used by enterprises for sanitary-technical purposes and are installed in metallurgical plants, CHPs, etc.

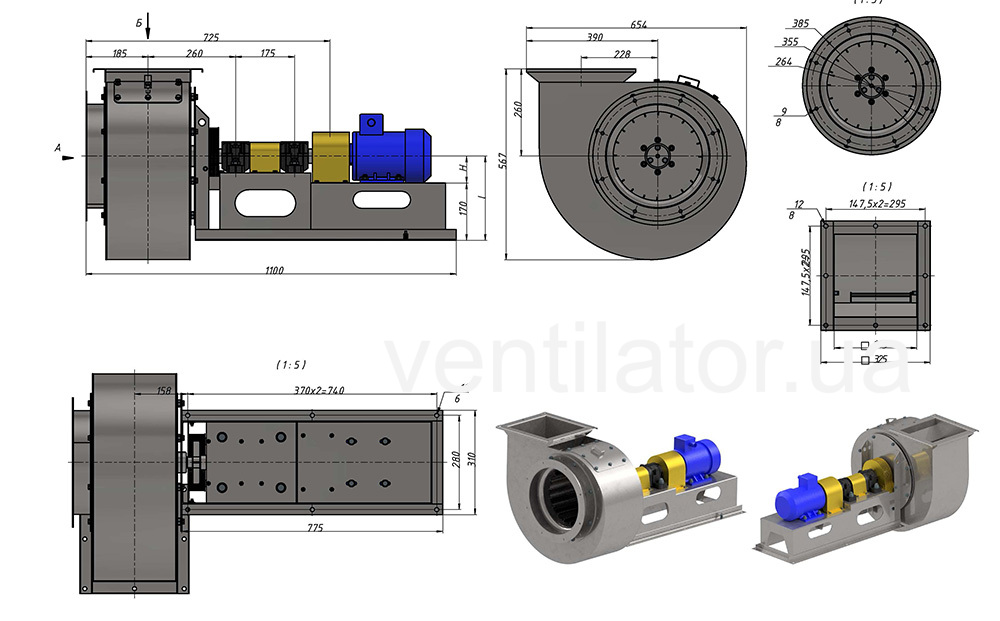

The smoke exhauster D 3,5 consists of the following components, available separately:

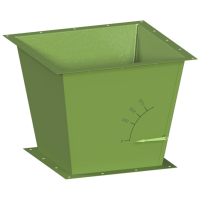

- Spiral rotating fan casing

- Impeller

- Frame (mounting base)

- Collector

- Electric motor Electric motor AIR 100 L4 4.0 Power kW 1500 Vol./Min

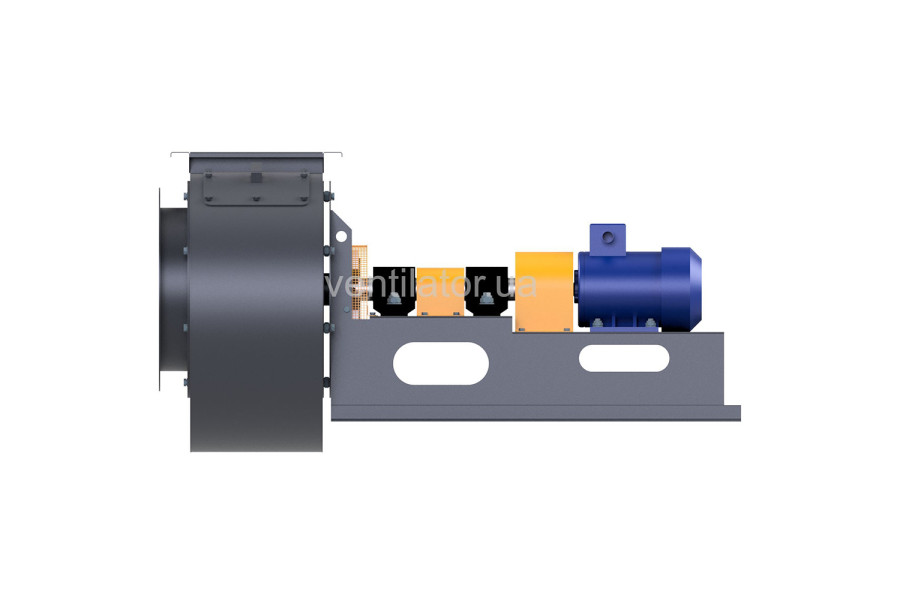

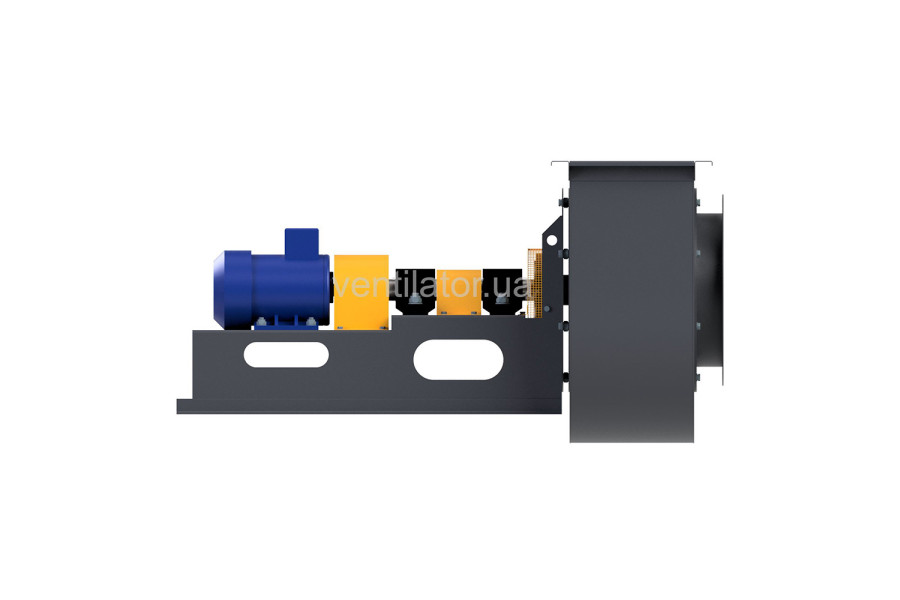

The welded spiral casing of the D 3.5 w/motor AIR 100 L4 4 kW 1500 rpm smoke exhauster is made from carbon steel. The impeller is of overhung design with forward-curved blades. The assembly includes the base frame, collector, and a three-phase AIR asynchronous motor with squirrel-cage rotor (2.2 or 3.0 kW, 380 V/50 Hz).

In configuration No. 3, the impeller is mounted on the drive shaft via a bearing assembly. Designed for continuous operation, durability is achieved through reinforced casing walls and hard-alloy blade surfacing. Blade inlet/outlet angles are optimized for uninterrupted gas flow.

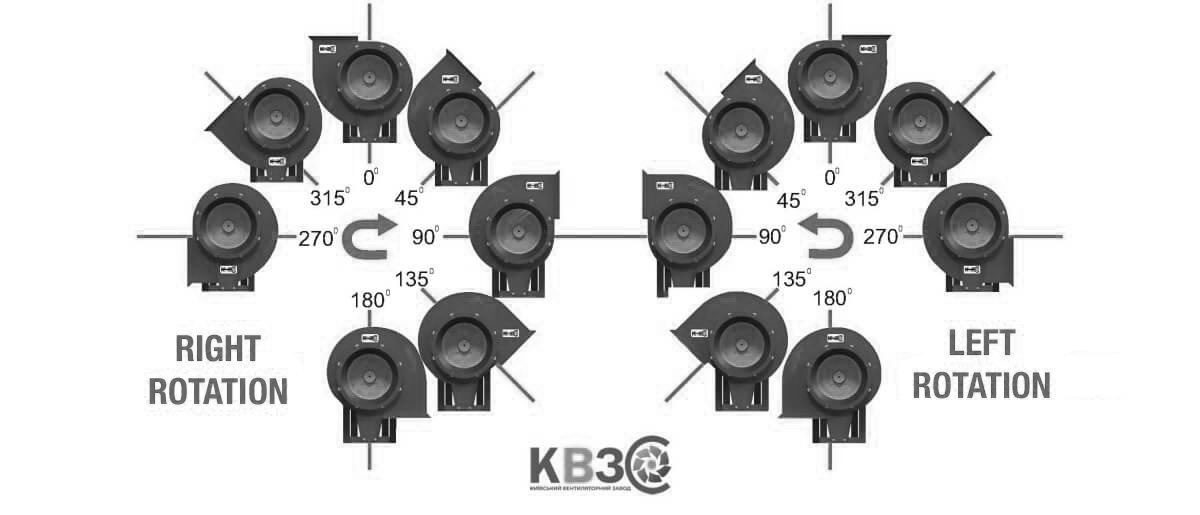

The unit can be configured for right- or left-hand rotation; the casing orientation is adjustable within a 0–270° range.

General information about D 3.5 w/motor AIR 100 L4 4 kW 1500 rpm smoke exhausters:

- Single-sided intake

- Spiral rotating casing

- Forward-curved blades

- Number of blades: 20

- Rotation direction: right or left (viewed from motor side)

Applications of D 3.5 w/motor AIR 100 L4 4 kW 1500 rpm smoke exhausters:

These units are used in power engineering as flue-gas removal equipment, designed for steam and hot-water boilers with up to 25 t/h (20 MW) output, burning various fuels. They require an effective ash collection system. They are built for continuous indoor and outdoor operation in moderate climates. Start-up is allowed at casing temperatures no lower than –30 °C. Maximum flue gas inlet temperature: +180 °C.

Also suitable for use on gas/fuel oil-fired boilers and in industrial installations in metallurgy, chemical, and power sectors, especially in gas and dust removal systems.

D 3.5 w/motor AIR 100 L4 4 kW 1500 rpm smoke exhausters are used in:

- Power stations

- Gas/fuel oil boiler systems

- Steam and hot-water boilers

- Sanitary-industrial applications

The maximum temperature of conveyed media must not exceed 250 °C.

Operating principle of D 3.5 w/motor AIR 100 L4 4 kW 1500 rpm:

The fan operates by transferring rotational energy from the impeller, mounted on the motor shaft, to the gas. The mixture enters through the collector into inter-blade channels, where centrifugal force pushes it outward. The flow is then deflected by 90° and discharged through the spiral casing.

Operating conditions for D 3.5 w/motor AIR 100 L4 4 kW 1500 rpm:

- Carbon steel body—max flue gas temperature: +200 °C

- Start-up allowed when inlet air ≥ –30 °C

- Ambient temperature: –40…+40 °C

- Vibration intensity ≤ 2 mm/s RMS from external sources

- Solid particle content ≤ 2 g/m³ in flue gases

Casing orientation for right-hand (PR) and left-hand (LV) rotation (view from intake side):

a) right-hand rotation

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.

No questions about this product, be the first and ask your question.