The D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm industrial smoke exhauster, manufactured according to design scheme No. 3 – drive to the impeller via an intermediate shaft.

The D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm industrial smoke exhauster, manufactured according to design scheme No. 3 – drive to the impeller via an intermediate shaft.

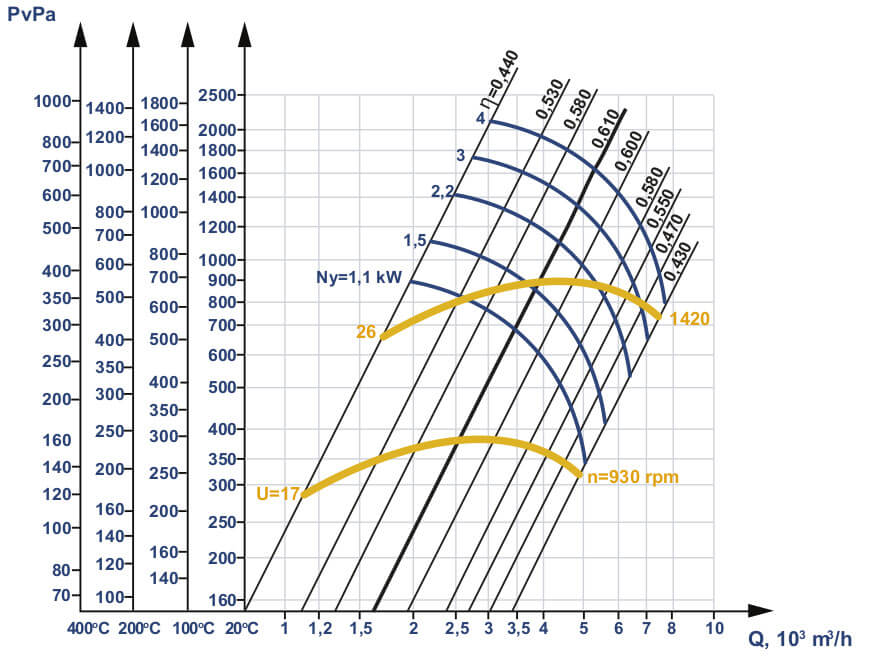

The D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm smoke exhauster is designed to remove gases from small-capacity boiler plants with a capacity of up to 1 ton of steam per hour, operating on gas and fuel oil. The temperature of the transported gases must not exceed 200°C for smoke exhausters with an impeller made of St3 steel and 400°C for an impeller made of heat-resistant steel grade 09G2S. It is also used for sanitary and technical purposes at metallurgical plants, thermal power stations, etc. Ambient temperature: from -40°C to +40°C.

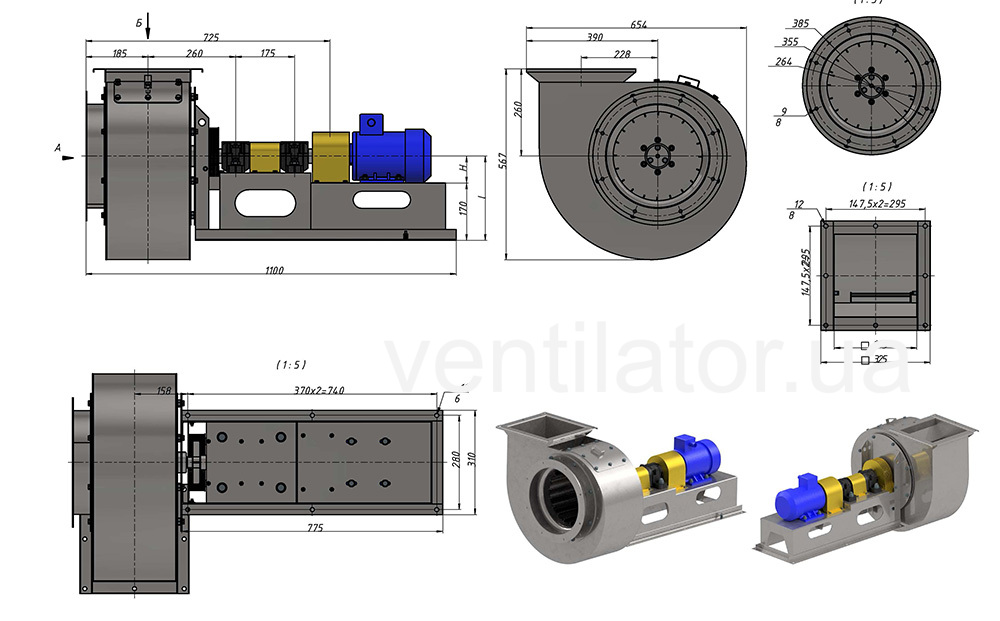

The smoke exhauster D 3,5M consists of the following components, which can be purchased separately:

The welded spiral housing of the D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm smoke exhauster is made of carbon steel; the impeller (overhung arrangement) has forward-curved blades, with base frame, collector, and three-phase Electric motor AIR 80 B6.

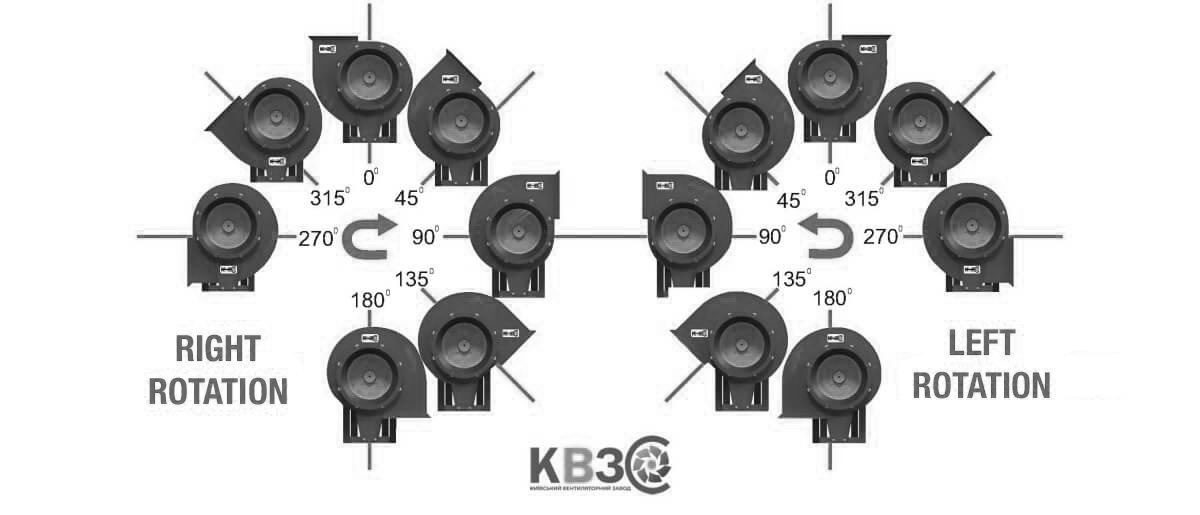

The D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm smoke exhauster with installation scheme #3 has the impeller connected to the drive shaft through a bearing assembly. It is designed for long-term operation; wear resistance is ensured by thickened scroll walls and the application of hard surfacing on the blades. Smooth gas flow is ensured by specially selected inlet and outlet angles of the blades. The smoke exhauster can be made for right- or left-hand rotation; the housing can be rotated from 0 to 270 degrees.

General information about D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm smoke exhausters:

Purpose of D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm smoke exhausters:

The D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm smoke exhauster is intended for use in power engineering as an exhaust device for equipping steam and hot-water boilers with balanced draft of low and medium capacity (up to 25 t of steam per hour or 20 MW) operating on various types of fuel. The smoke exhauster must be equipped with an effective ash trapping system. Designed for continuous operation both indoors and outdoors in temperate climates. Startup is permitted when the temperature in the housing is not lower than -30°C. The maximum temperature of gases at the smoke exhauster inlet should not exceed +250°C.

Use is permitted with gas and oil-fired boilers with balanced draft, as well as in process installations at enterprises in various industries for sanitary and technical or production purposes (at thermal power plants, metallurgical plants, in chemical industry for gas cleaning and dust collection, etc.).

D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm smoke exhausters are used in:

Operating principle of the D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm smoke exhauster:

The operating principle of the fan is to move air by transferring the rotational energy of the impeller mounted on the motor shaft. The air mixture entering through the collector passes into the channels between the impeller blades and, under the action of centrifugal force, moves to the periphery of the impeller. The smoke gases with air enter the smoke exhauster by receiving energy from the impeller, are deflected 90 degrees in the radial direction by centrifugal force, and are discharged through the scroll housing to the fan outlet.

Operating conditions of the D 3.5M w/motor AIR 80 B6 1.1 kW 1000 rpm smoke exhauster:

Positions of the housing for right-hand (RH) and left-hand (LH) rotation, as viewed from the inlet:

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.