Cyclone dust collector COL-1

Purpose of Cyclones COL-1

The COL-1 cyclones are designed to clean the air coming from aspiration and pneumatic transport systems from coarse dust and impurities. They effectively capture sawdust, grain dust, weeds, and other particles larger than 126 μm. The efficiency of trapping coarse grain dust is around 95–98 %.

Air Cleaning Process COL-1

- Dust-laden air with impurities enters the cyclone body.

- Due to centrifugal force, particles settle on the walls and spiral downward into the hopper.

- Clean air rises upward and exits through the top outlet.

- Dust and debris are collected at the bottom of the cyclone.

Design Features

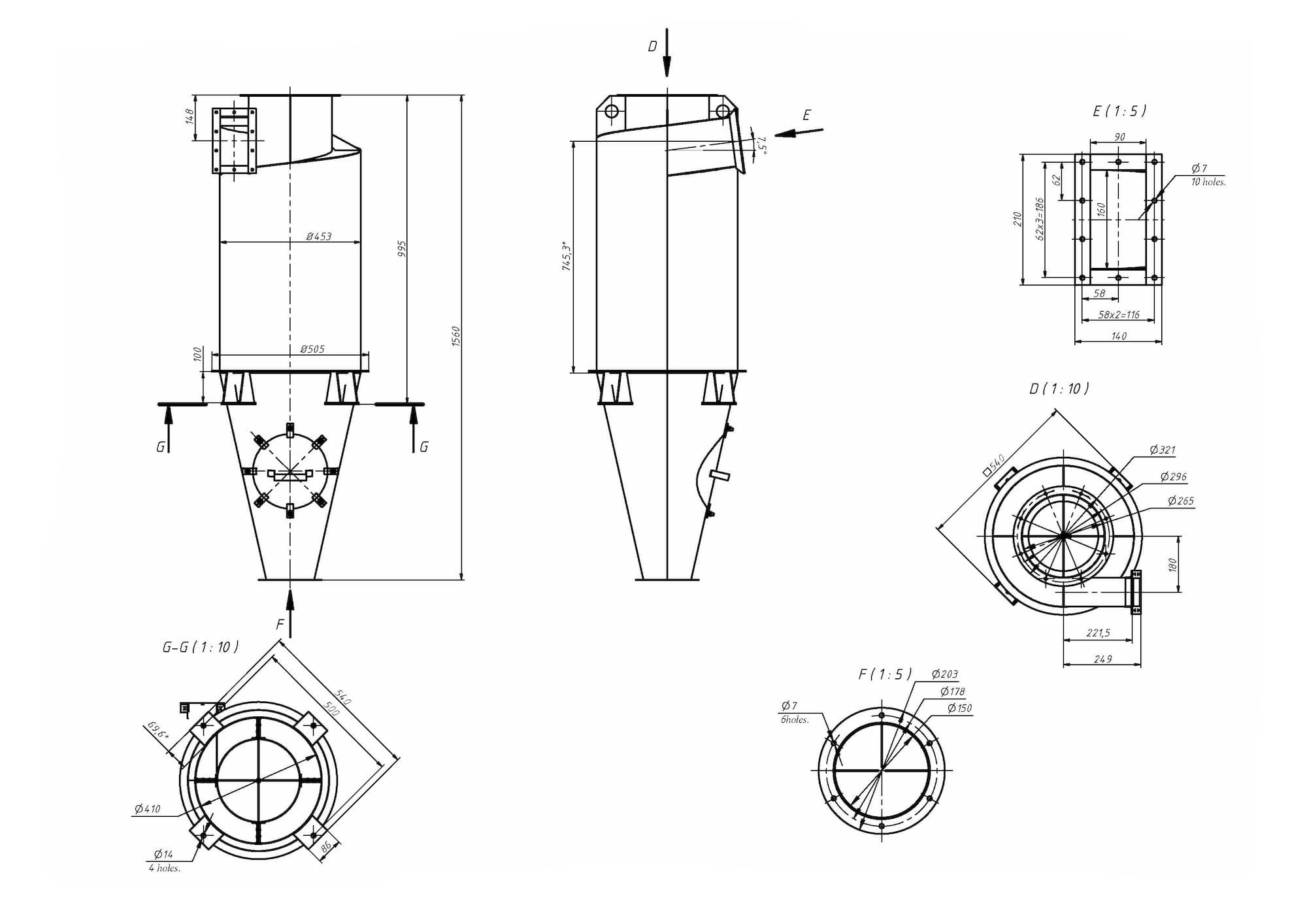

Standard COL-1 cyclones are manufactured from welded steel sheet. Inlet and outlet pipes are connected to the ductwork via flanges or adapters. To prevent corrosion, all surfaces are primed and coated. Available in both right-hand and left-hand versions, with optional hopper, umbrella, or snail casing. A unique feature is the anti-suction cone device, which helps stabilize pressure at the cyclone inlet.

Installation of Cyclones

Cyclones of the COL series are installed together with a fan. There are two possible installation options:

- before the fan;

- after the fan.

For grain dust removal, both options are considered equally effective. If the fan is installed after the cyclone, a special flow stabilizer (straightener) must be used.

Specifications

- Used as first-stage dust collectors in aspiration systems.

- Fractional dust collection efficiency:

- 2.5…63.0 μm – 48.7 %

- 63.0…100.0 μm – 55.3 %

- 100.0…160.0 μm – 63.3 %

- 160.0…400.0 μm – 68.1 %

- 400.0…630.0 μm – 74.1 %

- 630.0…1000.0 μm – 78.9 %

- Maximum inlet air velocity – 18 m/s.

- Maximum dust concentration at inlet – 10×10⁻³ kg/m³.

- Hydraulic resistance of a single cyclone at operating speed – ξ = 4.0.

Technical Data

- Design – single cyclone of Liote type.

- Series includes 10 standard sizes and 3 additional ones.

- When operating under pressure, equipped with an umbrella; when under suction, equipped with a snail casing.

- Material – steel from 2 mm thick, primed and painted light gray (RAL7035).

- Welded construction.

- A hatch is provided in the conical part for inspection and maintenance.

- The cylindrical part can be rotated relative to the cone axis at an angle:

- 30° – for COL (1–3);

- 22°30′ – for COL (4.5–9);

- 15° – for COL (12–20).

- Possible hopper gate valve options:

- 6 L – for COL (1–1.5);

- 9 L – for COL (3–6);

- 15 L – for COL (9–12);

- 22 L – for COL (15–20).

- Climatic version – U, placement category 1 (outdoor use).

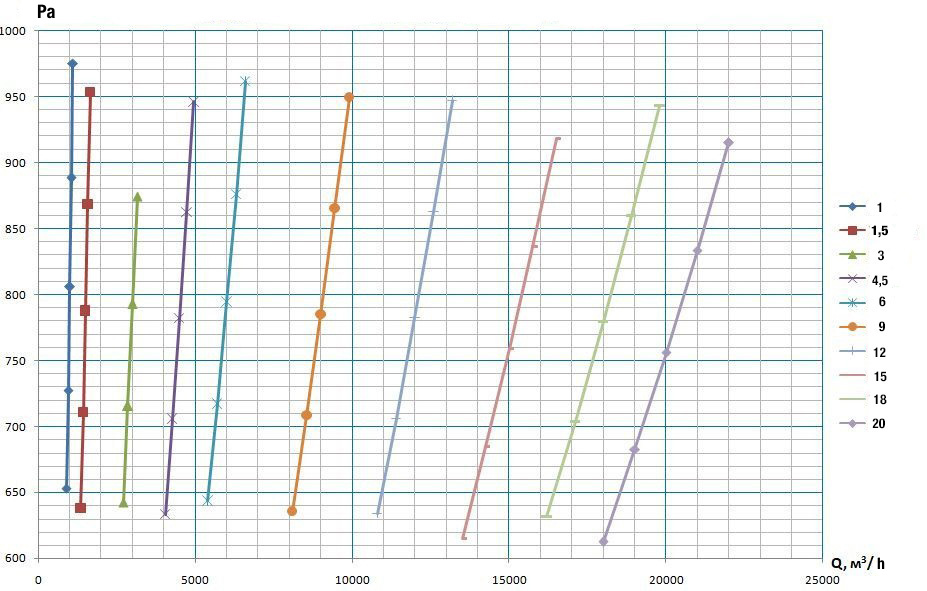

Aerodynamic resistance of COL cyclones

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.