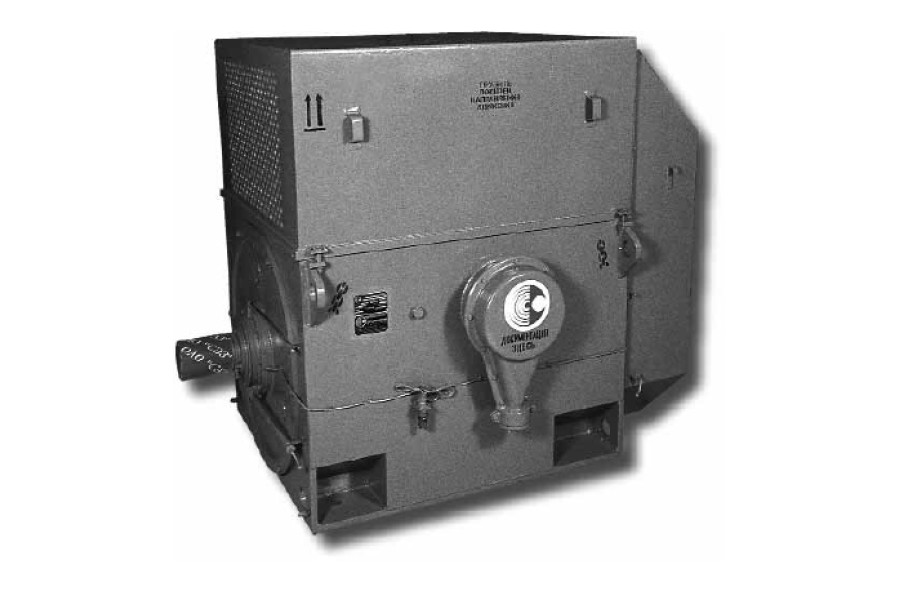

General information about asynchronous electric motor AOD-1600/800-12/16U1

AOD motors are asynchronous squirrel-cage motors with a power of up to 1600 kW, designed for driving mechanisms with severe starting conditions (smoke exhausters, mechanisms and fans with similar characteristics).

Motors are classified by number of poles and power.

Motor AOD-1600/800-12/16U1 is built with shielded sliding bearings. Bearing lubrication: ring-type, autonomous or combined (forced and ring-type).

Characteristics of asynchronous electric motor AOD-1600/800-12/16U1

Climate version – U1.

Rated duty – S1.

Mechanical design group – М6.

Construction version of the motors – IM1101.

Cooling method of the motors – 1SAO1A61.

Degree of protection – IP 44/54, terminal boxes – IP54-55.

Design of asynchronous electric motor AOD-1600/800-12/16U1

The output devices of the AOD motor are designed for connection of aluminum and copper cables and for splitting cables followed by filling the splitting area with cable compound on dry separation.

Stator winding connection – “star”.

The rotor winding is squirrel-cage, made of copper or aluminum rectangular bars welded into the short-circuiting rings.

Motors allow right-hand rotation. Left-hand rotation can be provided upon customer request.

Cooling air for the outer circuit is taken from the surrounding space by a centrifugal fan on the side opposite the driven equipment and is supplied to the tubes of the air cooler, then exhausted on the driven equipment side.

Stator winding insulation is made using thermosetting binders and is used in the motors at overheating corresponding to class B – maximum allowable continuous temperature of 130°C.

Operating conditions of asynchronous electric motor AOD-1600/800-12/16U1

Altitude up to 1000 m above sea level.

Relative air humidity not exceeding 80% at a temperature of 20 ºC.

Atmosphere type II according to DSTU 15150-69.

Ambient air must not contain explosive or fire-hazardous substances, as well as chemically aggressive contaminants.

Allowable noise levels for the motors comply with DSTU 16372-93.

Safety requirements for the motors comply with DSTU 12.2.007.0-75 and DSTU 12.2.007.1-75. Allowable vibration of the motors complies with DSTU 20815-93.

Motors, except versions with Monolit-2 insulation for U1 placement category, are supplied with built-in space heaters.

Direct starting of AOD motors is allowed at full network voltage if the terminal voltage during starting is not less than 0.8 Un.

Two consecutive starts from cold state or one start after prolonged operation under load are permitted. Subsequent starts are allowed after at least 3 hours. Total number of starts – 500 per year and 10,000 over the entire service life.

AOD motors allow two starts per day (up to six during commissioning).

Allowable starting modes of AOD motors are determined during the verification of their suitability for the specific driven equipment.