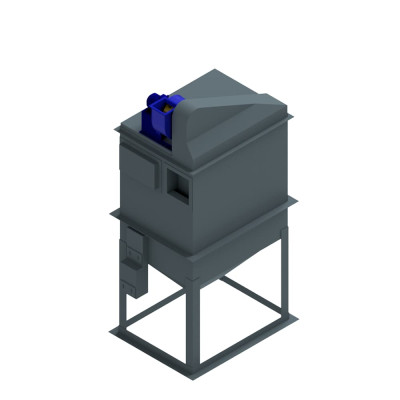

Dust collectors PVM

Dust collectors of the PVM class — units for cleaning the air removed by ventilation exhaust systems from medium and fine dust, including explosive and fibrous. They are designed for cleaning the air in the premises of production facilities of categories B and D and provide a high level of cleaning efficiency.

The universal cyclone-dust collector ventilation wet PVM, which can now be purchased in Ukraine, is capable of catching fine particles of dust and sludge formed during industrial production. It is recommended to use PVM dust collectors in aspiration systems to increase the degree of industrial air purification and reduce unpleasant odors.

PVM dust collectors are used for air purification in various industries — woodworking, food, chemical and metallurgical. They effectively remove fine dust, grinding dust and fibrous inclusions.

PVM units are recommended for use in both the first and second stages of air flow purification. These PVM dust collectors are made of high-quality metal, ensuring long-term operation and stable performance. During operation of dust collectors, it is recommended to monitor the amount of sludge in the outer compartments to avoid overload.

Marking of the PVM class dust collector

«PVM - 5SA», «PVM - 10SA», «PVM - 20SA», «PVM - 40SA», where:

- «P» — dust collector;

- «B» — ventilation;

- «M» — wet;

- Number (5, 10, 20, 40) — corresponding unit performance in m³/h;

- «CA» — presence of a sludge drainage system or scraping mechanism.

PVM can be purchased in Kyiv directly from the manufacturer through the Ventilator.ua online store, where all documentation is available — passport and operating instructions, drawings and technical specifications. This allows you to select the unit for specific production parameters and ensure correct installation. In industrial use, PVM 5CA and 10CA dust collectors are recommended for air where the concentration of dust particles in the air is more than 10 g/m³ and where recirculation is allowed.

Design advantages

The metal housing of the PVM class dust collectors consists of a lower and upper zones. In the lower part there are partitions that form a channel for the passage of air and sludge. Fine dust particles settle at the bottom of the housing, and the purified industrial air passes through the droplet traps and is removed by a ventilation fan.

The dust collectors are equipped with sensors that perform an emergency stop of the fan when the water level drops below the limit value. PVM industrial dust collectors allow the aspiration of dust particles from local exhaust systems, which increases the safety of the production process and reduces the risk of the formation of fungi and bacteria.

The housing of the PVM 5SA, PVM 10SA and PVM 20SA dust collectors is made of carbon steel. PVM 40SA - an upgraded model with improved parameters, which allows to reduce aerodynamic resistance, maintains a high level of capture of fine and medium-sized dust particles and provides the ability to connect an umbrella for air recirculation.

PVM is recommended for use in industrial-type premises, where it is important to maintain stable performance and duration of operation.

Operating principle

Air with contaminants enters the dust collector through the inlet pipe, passes through the channel between the partitions and the water surface at a speed that ensures maximum capture of fine particles of dust and grinding dust. In the «SA» series, sludge removal is carried out by draining through a valve, in the «KB» and «KMA» series - by means of a scraper mechanism, and in the «B» series — through side pockets. The degree of air purification reaches 99% even with a high concentration of dust particles.

PVM 5SA and PVM 10SA are designed for small rooms, PVM 20SA — for medium-sized workshops, and PVM 40SA — for large industrial workshops and grinding plants. It is recommended to use these units as a second stage of purification after a dry dust collector. The use of PVM industrial dust collectors in aspiration systems allows you to minimize unpleasant odors, avoid the accumulation of fungi and bacteria, and maintain a stable air flow in the outer compartments.

PVM dust collector comparison table

|

Model of the PVM

|

Productivity, m³/h

|

Cylinder diameter, mm

|

Height, mm

|

Cleaning efficiency

|

Features

|

Usage

|

|

PVM 5СА

|

3000–6000

|

1315–1500

|

3185–3500

|

up to 98%

|

Sludge drainage system, water level sensors

|

Small rooms, fine dust aspiration systems, grinding

|

|

PVM 10SA

|

6000–10000

|

1500–2000

|

3500–3800

|

up to 98–99%

|

Scraper mechanism for sludge removal, level switch, emergency fan stop

|

Medium-sized workshops, cereal and woodworking industries, fine and medium-dispersion dust

|

|

PVM 20SA

|

10000–20000

|

2000–3000

|

3800–4200

|

up to 99%

|

Scraper mechanism + side pockets for sludge, increased explosion hazard

|

Large production facilities, aspiration units for pneumatic transport, medium and fine dust

|

|

PVM 40СА

|

20000-40000

|

3000-4385

|

4200-5010

|

up to 99-99.5%

|

Modernized body, reduced aerodynamic resistance, possibility of connecting an umbrella, spare parts from the manufacturer

|

Grinding plants, large woodworking and flour milling plants, ventilation systems with increased concentration dust

|

Advantages

- Versatility and possibility of use in various industries;

- High efficiency of cleaning fine and medium dust;

- Possibility of air recirculation in production premises;

- Easy installation and maintenance, availability of spare parts and an umbrella to reduce aerodynamic resistance;

- Protection of the fan and system from excessive load;

- Dust collectors equipped with sensors ensure safety and the ability to perform an emergency stop of the fan when the water level drops;

- Control of the amount of sludge in the outer compartments to ensure stable operation of the unit.

Sludge from the unit is removed by draining into a pocket, which provides fast and safe cleaning.

Dust collectors are manufactured in accordance with GOST, which guarantees compliance with quality and reliability standards.

Aspiration systems are designed to minimize the spread of fungi in the air of production premises.

Ventilation units are equipped with filters that reduce the concentration of bacteria in the air and ensure safe operation.

Field of application

PVM dust collectors are used in woodworking, flour milling, cereal workshops, in the food and metallurgical industries. The units provide effective removal of grinding dust, fine dust particles, sawdust and wood. PVM dust collectors are recommended for rooms of categories B and D, where aspiration and air purification in a safe way is important, such as extreme compartments. The exception is rooms where there are substances of hazard class 1, high concentrations of fungi or bacteria, in the air of which recirculation is not allowed.

Where to buy a PVM dust collector in Kiev and Ukraine

You can buy PVM in Kiev through the official website of the Ventilator.ua factory. Delivery across Ukraine ensures quick delivery of PVM dust collectors of any model. Each dust collector is supplied with a passport and operating instructions, drawings, photos and technical specifications, which allows for proper installation and connection to the ventilation system.

These PVM dust collectors are recommended for use in production rooms of categories B and D, where it is important to maintain high efficiency of air purification from fine dust, grinding dust and sawdust. The presence of an umbrella and spare parts allows you to reduce aerodynamic resistance, ensure stable air flow and extend the service life of the units.