7900

934

750

10450

1648

1000

6700

2180

1500

500

37

1000

970

150

1500

84800

3190

585

970

150

3000

1100

100

1500

60000

4991

990

60000

4990

990

34000

3720

970

26950

2110

730

20600

2540

970

15500

1450

730

What are smoke exhausters: Main functions and applications

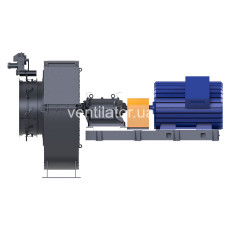

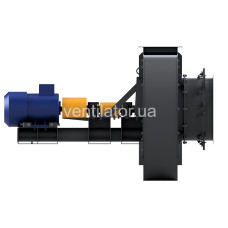

Smoke exhausters — are industrial fans that provide removal of smoke gases from furnaces, boiler rooms, furnaces and heat supply systems. They are used to remove combustion products, as well as to supply air to the furnaces. Thanks to their reliable design, these units can withstand high temperatures, aggressive environments and constant loads. The VD, VDN and DN models are often used – they can be purchased on the website of our design and installation company at the best price from the manufacturer.

Smoke exhausters are important in ensuring forced draft in boiler rooms, thermal power plants, industrial enterprises. They are also used to move air and non-aggressive gases, maintain stable draft in pipelines, which is especially important for the safety of objects in explosive environments.

Gravity machines: Principle of operation

Gravity machines combine the functions of smoke exhausters and blower fans. The principle of operation is based on the centrifugal effect - air or smoke enters the suction hole, where an impeller with curved blades, rotating clockwise, creates pressure and directs the flow in the desired direction.

The machines are structurally made of carbon steel, aluminum or dissimilar metals that can withstand high temperatures and chemical aggressiveness. Some models are equipped with additional cooling, which allows them to operate at temperatures above 250°C. This is an ideal choice for boiler houses, metallurgical plants, heat generators.

Where used: Industry, boiler houses, ventilation systems

Chimney fans and blower fans are used in the following industries:

- Boiler plants (gas, coal, pellet)

- Metallurgical enterprises — for the removal of smoke, hot gases and dust

- Waste incineration plants

- Food and chemical industry

- Ventilation systems of enterprises

- Heat generators in the agricultural sector.

The use of these units allows you to ensure stable combustion, oxygen supply, removal of hazardous gases and maintenance of the temperature regime in combustion chambers. The function of air movement in closed or complex ventilation systems is especially valuable.

Key advantages: High performance, durability

Chimney fans and draft fans have a number of key advantages:

- High performance — provide effective air/gas movement

- Strength and reliability — the housing is made of thick-walled steel or alloys

- Resistance to aggressive environments — not afraid of moisture, soot, dust

- Low noise level — due to a balanced impeller

- Long service life — minimal maintenance

- Versatile application — one unit for different types of furnaces

- Optimal price/quality ratio.

In addition, all models undergo additional balancing and testing, which guarantees safety and stable operation even in conditions of high humidity or temperature.

Choosing the optimal model: Main parameters

When choosing a smoke exhauster or a gravity machine, you should pay attention to the following characteristics:

- Fan type: VD, VDN, DN

- Motor power: from 1.1 to 35 kW

- Impeller diameter

- Temperature mode: standard (up to 200°C) or heat-resistant (up to 400°C)

Productivity (m³/h) - Direction of rotation blades

- Body and impeller material

- Number of revolutions/minute

- Availability of noise insulation

For more detailed information, contact our managers — they will tell you which smoke extractor is best suited for your facility. You can also buy a VDN smoke extractor, a DN smoke extractor, or a blow industrial fan with delivery throughout Ukraine.

The Ventilator.ua website presents a wide selection of smoke extractors and gravity machines from the manufacturer KVZ. Our catalog includes models with different configurations, sizes, power, at affordable prices. You can buy smoke extractors with a guarantee, fast delivery across Ukraine and expert advice.

Don't delay — order online or call to get detailed information and equipment selection for your task. All fans and smoke extractors are certified, and our company's products and services meet European standards.

Prices for induced- and forced-draft fans

| Name | Product code | Price, UAH incl. VAT |

|---|---|---|

| D 3.5M (modernized) with electric motor AIR 90 L4 2.2 kW 1500 rpm | id10773 | 25 979 |

| D 3.5M (modernized) with electric motor AIR 100 S4 3 kW 1500 rpm | id10774 | 27 385 |

| DN No. 12.5 with electric motor AIR 250 S4 75 kW 1500 rpm | id31211 | 293 002 |

| DN No. 6.3 with electric motor AIR 112 M4 5.5 kW 1500 rpm | id10907 | 191 406 |

| VD-2.7 | id16321 | 17 727 |

| D 3.5M (modernized) with electric motor AIR 80 A6 0.75 kW 1000 rpm | id10722 | 22 629 |

| D 3.5M (modernized) with electric motor AIR 80 B6 1.1 kW 1000 rpm | id10771 | 23 209 |

| DN No. 17 with electric motor AIR 355 S6 160 kW 1000 rpm | id11095 | 1 522 440 |

| DN No. 6.3 with electric motor AIR 100 L4 4 kW 1500 rpm | id10906 | 187 273 |

| VD-3.5 | id16549 | 22 715 |