A smoke exhauster is a centrifugal fan that ensures the stable operation of the smoke extraction system during the operation of industrial heating equipment. It creates the necessary pressure and guarantees the increase in draft required for the safe removal of fumes from the furnace. Smoke exhausters are used in almost every modern ventilation system.

Function of the smoke exhauster

The smoke exhauster creates the necessary vacuum for the stable movement of smoke inside the chimney. Its main function is to ensure the effective removal of gases even when natural draft is insufficient. Such a solution is especially relevant for heating systems where the stability of the combustion process determines the quality of equipment operation. The use of a smoke exhauster allows maintaining an optimal mode and increasing the reliability of the heating installation.

How a smoke exhauster works: principle of operation

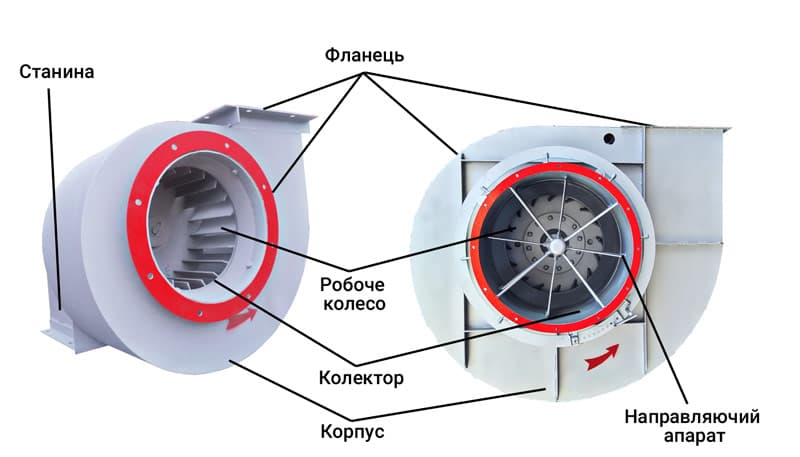

Most models use a centrifugal mechanism that allows effectively moving the flow of flue gases. The operating principle of the smoke exhauster is based on the high-speed rotation of the fan impeller. During the rotation of the blades, a directed air flow with the required level of vacuum is created. The key element of the drive is the shaft, which connects the electric motor and the impeller of the smoke exhauster. It is through the shaft that the torque is transmitted, ensuring the high-speed rotation of the blades and the formation of the necessary pressure difference. This ensures intensive suction and movement of air together with smoke particles into the chimney pipe. Such a mechanism allows venting flue gases through the chimney even in unstable operating modes and maintaining draft where the system cannot cope without it.

The general structure of a smoke exhauster consists of a working chamber, a scroll casing (volute), blades, and an impeller. Centrifugal industrial fans have housings made of durable carbon steel, which guarantees a long service life and protection against high loads. If the device operates in an aggressive environment, preference is given to stainless steel models.

Pressure increase and removal of combustion products

Efficient air movement increases the pressure inside the smoke exhauster housing, which helps to move the flow unimpeded and perform complete removal of combustion products. In such systems, the correct selection of the fan is important, as the level of performance and stable air movement depend on it. Optimal parameters allow avoiding gas accumulation, improving efficiency, and the operation of heating equipment. Even during intensive fuel combustion, the system works evenly and guarantees a safe mode. The unit installed at the outlet creates stable pressure, thanks to which the smoke exhauster ensures complete cleaning of the channel along the entire path of air movement.

Where smoke exhausters are used

Smoke exhausters are necessary where the operation of heating boilers depends on stable draft and the correct movement of air flows. Such systems support equipment efficiency and maintain combustion process stability at any load level. Main areas of application of the smoke exhauster:

- boiler rooms at industrial facilities requiring powerful thermal units;

- heating systems of private houses and heating boilers;

- facilities where it is necessary to stabilize the draft in the chimney;

- equipment using different types of fuel;

- structures where channel protection and correct removal of carbon monoxide are important.

Such equipment is often installed in rooms where it is important to reduce the load on the chimney during peak modes. In such cases, the smoke exhauster maintains uniform draft so that the boiler works without overloads and sharp fluctuations in performance.

Types of smoke exhausters

The variety of designs allows choosing exactly the smoke exhauster that best suits the operating conditions and system features. Before choosing a smoke exhauster, it is important to consider the nuances of the models to understand which devices will give the best result. The list of important parameters for selecting smoke exhausters includes:

- operating temperature range;

- nature of combustion;

- load conditions;

- pressure generated in the process;

- housing materials;

- resistance to aggressive environments.

The online store Ventilator.ua offers modern smoke exhausters for solid fuel boilers at the best prices with delivery across Ukraine. A large selection of models in the company's catalog allows precisely selecting a smoke exhauster for a domestic boiler, taking into account the power of the electric motor.

Low / medium pressure

A smoke exhauster for a domestic boiler is installed where support for the combustion process and efficient movement of air flows without excessive load on ventilation is needed. Low and medium pressure smoke exhausters are ideal for installation in small boiler rooms and individual heating systems of private houses. The high performance of the devices ensures controlled draft in the ventilation channel of the heating device. They have an optimal working chamber diameter and sufficient impeller area, which contributes to the complete removal of carbon monoxide gases.

High pressure

Smoke exhausters producing high pressure are designed for difficult conditions. They ensure intensive movement of gas mixtures into the chimney and maintain good draft in the exhaust. A smoke exhauster for a solid fuel boiler with high pressure is installed in large heating complexes, steam or hot water installations, as well as in places where it is important to ensure reliable removal of the gas flow. The power of the electric motor in each model reliably supports high revolutions and guarantees extraction even at maximum operating modes.

Heat-resistant

Smoke exhausters with increased resistance to high temperatures are created for jobs where it is important to preserve the strength of the housing and the stability of the fan even during long-term loading. Such models are often made of stainless steel or heat-resistant alloys, often with the addition of alloying elements, which allows them to withstand constant heating and ensure safe removal of hot air. A heat-resistant smoke exhauster for a solid fuel boiler has a special bearing design (roller or ball) of an open type or with protective metal washers (ZZ). The shape of the fan blades in heat-resistant smoke exhausters is created taking into account the thermal deformation of the metal and has a protective coating.

Explosion-proof

Smoke exhausters for solid fuel boilers, protected from the risk of explosion, are created for work in zones where dangerous mixtures of flue gases, vapors, or dust can form. Their design is aimed at completely eliminating ignition sources. The housing and impeller are made of non-sparking materials, and increased gaps are maintained inside to exclude friction between moving and fixed elements. Each motor in smoke exhausters of this series is created in the Ex explosion-proof standard, which prevents sparking or overheating during operation. Temperature control and protective relays of explosion-proof smoke exhausters monitor the equipment status and turn it off in case of overheating/overload. All equipment undergoes ATEX certification or is made in accordance with the technical regulations of Ukraine, which confirms the suitability of smoke exhausters for zones 1, 2, 21, and 22.

Main criteria for choosing a smoke exhauster

Selection of equipment for the stable operation of the smoke extraction system is based on a precise analysis of the operating modes of heat-generating units, structural features of chimneys, and room operating conditions. Technical parameters influence how confidently the smoke exhauster will work in different load modes. Before buying a smoke exhauster, it is necessary to consider:

- system pressure and channel configuration;

- gas operating temperature;

- fuel type and boiler operating mode;

- dust level;

- volume of air mixtures that the fan impeller must move.

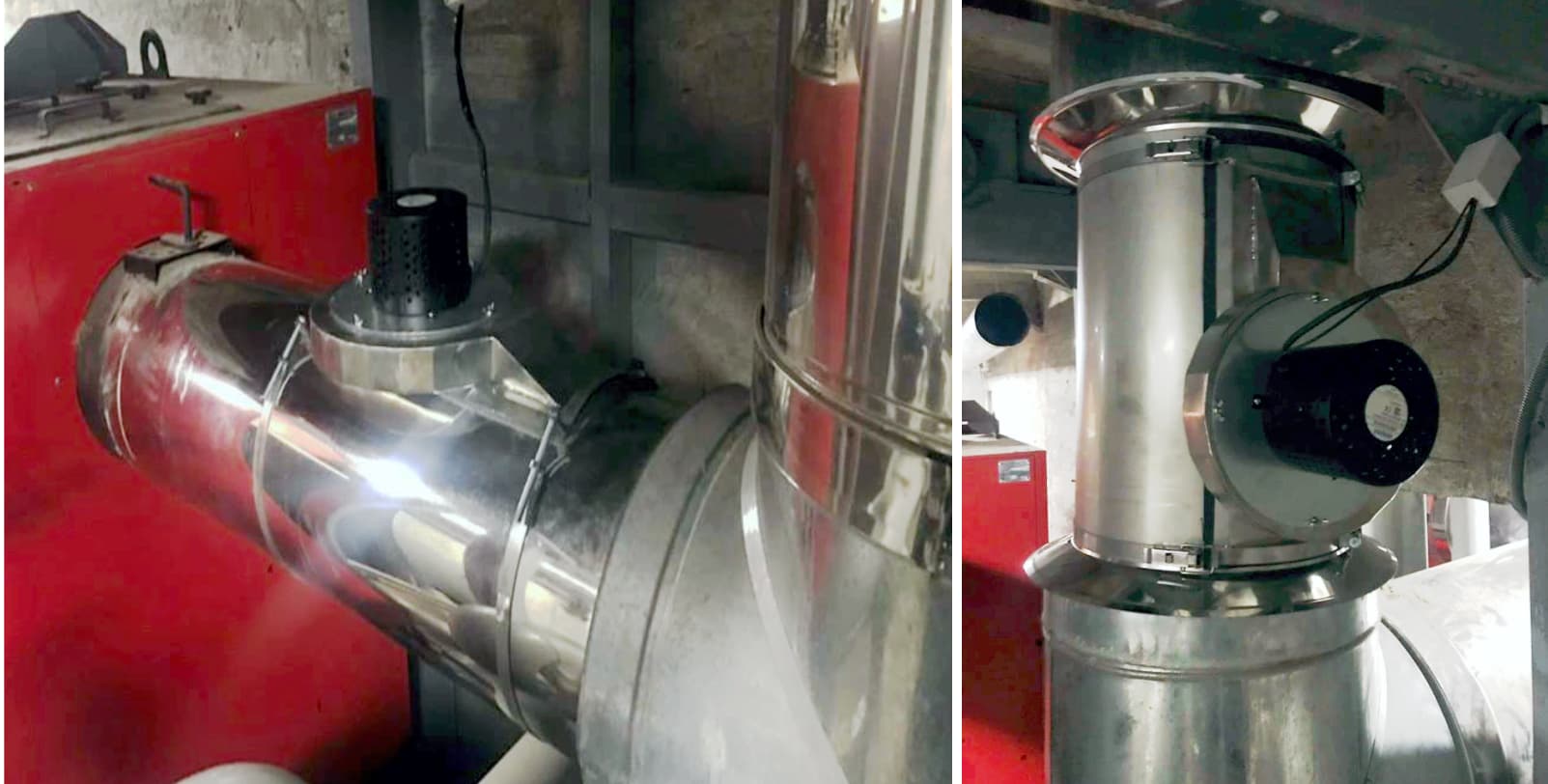

For a fireplace or a solid fuel heater, a duct smoke exhauster for a domestic boiler is often chosen — a compact solution that is installed without complex system modifications.

Smoke system pressure

Correct pressure in the smoke channel determines how easily the smoke exhauster moves gases to the chimney exit. If the pressure is too low, the draft weakens, and the smoke begins to move slowly and unevenly. If the pressure is too high, the system works with overload and consumes more energy than necessary. When selecting equipment, the height and diameter of the chimney, the number of turns, and exactly how carbon monoxide gases are discharged are taken into account. All these factors affect the level of vacuum that the smoke exhauster must create so that the air-gas mixture moves stably to the exit and does not linger in the ventilation channel.

Operating temperature

Thermal stability of the equipment determines how the smoke exhauster behaves during long-term operation. Flows passing through the chimney channel have a variable temperature depending on:

- combustion mode;

- type of heat-generating equipment;

- gas movement speed.

The temperature of flue gases in the chimney of a solid fuel boiler is usually from +160°C to +400°C, and in some cases can reach 500°C, which requires the smoke exhauster to be able to work in this range without loss of mechanical stability. Manufacturers offer models designed for constant operation at temperatures up to +200°C, such as the DN smoke exhauster, manufactured by KVZ.

Fuel type

The method of fuel combustion forms different flows of gas masses, so it is important to take into account the difference between coal, wood, pellets, and gas. Each option creates a different intensity of smoke movement, which is reflected in the selection of equipment. The fuel value affects how the suction channel works and what parameters must be maintained in the smoke extraction system. Some units require a special mode to maintain the declared efficiency, so the correspondence of the heat generator and the smoke exhauster allows maintaining operational stability in different cycles.

Boiler power

During boiler operation, its thermal power determines what volume of flue gases needs to be removed, so the smoke exhauster is selected based on two key parameters: capacity and pressure. Capacity (m³/h) must correspond to the actual volume of combustion products produced by boilers at thermal output. Fan pressure must be sufficient to stably push this volume of gases through the combustion chamber and chimney, avoiding draft sag. If at least one of the smoke exhauster parameters is less than the boiler's needs, gases do not have time to exit, unstable combustion, backdraft, and the risk of overheating appear. That is why the boiler power is always correlated with the throughput and pressure of the smoke exhauster — this guarantees even draft and safe operation of the entire system.

How to determine if a smoke exhauster is needed

In boiler rooms and domestic systems, a smoke exhauster for a boiler often becomes the only way to stabilize heating operation. Forced smoke extraction is needed if the system observes:

- unstable draft;

- excess smoke in the room or near the chimney exit;

- noisy fan operation;

- reduced boiler efficiency and increased fuel consumption;

- intensive soot formation in the channel.

To choose the optimal smoke exhauster model, one must consider the unit's power, features of the boiler or fireplace channel, and pipe materials.

Advantages of smoke exhausters from Ventilator.ua

The Ventilator.ua company offers high-quality smoke exhausters for solid fuel boilers at affordable prices, for example, D series smoke exhausters or DN. All models are manufactured at the Kyiv Ventilation Plant in compliance with modern standards. Smoke exhausters of various series are provided with a guarantee, which confirms the durability and stable operation of devices in various conditions. Clients can count on full support in the process of choosing a model and recommendations for the correct installation of a smoke exhauster for a boiler with their own hands, which guarantees efficient and safe operation of the system. Fast delivery of ordered smoke exhausters across Ukraine and abroad is ensured.

Write a comment