The stable operation of boiler equipment directly depends on how the removal of flue gases is organized. Natural draft is often insufficient, so draft machines appear in the scheme, capable of managing gas movement in complex heat engineering systems.

What is a Smoke Exhauster and What Role Does It Play in the Smoke Extraction System

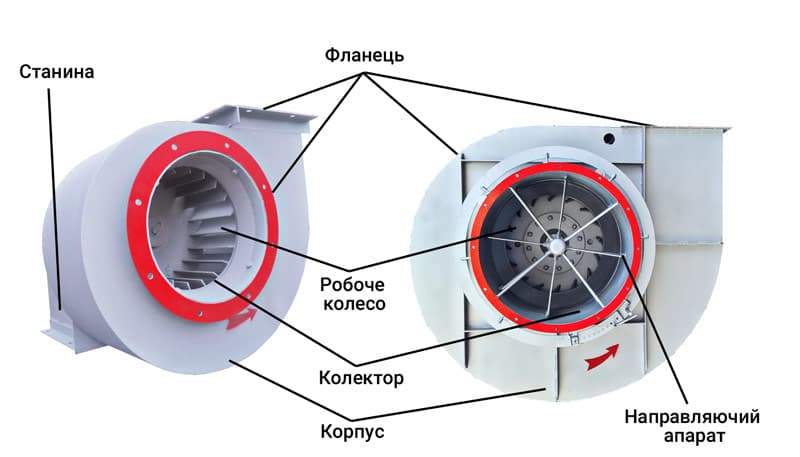

Any extraction system works as a single chain, where every link is important — from the furnace to the smoke channel. It is here that the need for specialized equipment is formed, which not only moves air but works with hot gas mixtures. Structurally, a smoke exhauster is a centrifugal fan adapted for working with hot flue gases and integrated into the boiler installation scheme. Its main characteristics are formed not only by aerodynamics but also by requirements for the temperature of combustion products, materials, and mechanical stability of units.

Purpose

The main function performed by the smoke exhauster is to create controlled draft in the furnace zone. Such a unit does not supply air but works at the outlet, forcibly removing combustion products from the boiler or group of boilers. This ensures the stability of the fuel combustion process, reduces the risk of backdraft, and allows precise control of the thermal regime. In industrial schemes, smoke exhausters are used as an element compensating for pressure losses in long gas ducts and filtration units. Controlled removal of combustion products stabilizes fuel combustion conditions, reduces pressure fluctuations, and maintains a predictable oxygen concentration in the air in the furnace zone. On the smoke exhauster market in Ukraine, products of LLC "Kyiv Fan Plant" and Vent Alliance company are in greatest demand.

Where It Is Used

The application of such devices covers a wide range of spheres — from local boiler rooms to large energy facilities. Most often, smoke exhausters can be used in systems of boiler units, heat generators, drying chambers, and technological lines with constant removal of hot smoke. A separate niche is occupied by a smoke exhauster for a boiler in industrial or municipal boiler rooms, where natural draft is unstable due to variable operating modes. Such solutions are also suitable for a solid fuel boiler in a private house, especially when working with biomass or coal.

Main Characteristics

To assess the efficiency of a smoke exhauster, it is important to consider operating parameters that determine its ability to adapt to a specific boiler installation. Performance and stability of operation are also affected by the fan location in the system, design features of air ducts, and interaction with other installation units. Key parameters by which the operation of a smoke exhauster is evaluated are directly related to aerodynamics and mechanics, these are:

- Capacity: the volume of smoke the unit is capable of moving per unit of time (m³/h).

- Total pressure: the ability of the smoke exhauster to overcome the aerodynamic resistance of the boiler and chimneys.

- Temperature regime: temperature of carbon monoxide at the inlet (usually up to +200...400 degrees Celsius), which determines the choice of heat-resistant steel and the need for shaft cooling.

- Impeller design: diameter, type of blades (curved forward or backward), and quality of their hardening for protection against abrasive wear by ash.

- Rotation speed: rotor speed, on which pressure and noise level depend.

- Motor: power and insulation heat resistance class for operation in high-temperature conditions.

- Housing execution: metal thickness and type of steel (carbon, stainless, or heat-resistant), which determines the service life in contact with an aggressive environment.

- Reliability of units: type of bearings, shaft design, and presence of a cooling system (cooling disk), which is critical for high temperatures.

- Mounting parameters: execution scheme (on one shaft with the motor or via a coupling), as well as nozzles of appropriate diameter through which the smoke exhauster connects to gas ducts.

- Mounting type and rotation angle: possibility of rotating the housing ("scroll") around its axis with a step of 15, 45, or 90 degrees, which allows precisely connecting the unit to the outlet channel at any angle.

- Maintainability: convenience of access to internal parts for cleaning blades from soot buildup and replacing bearings.

An important role in the device's operation is played by the impeller, as it determines the volume of gas flow movement. The scroll housing for smoke exhausters is optimal for creating significant vacuum in chimneys, but for specific conditions or compact systems, other design forms are used (axial or direct-flow, overhead).

How Smoke Exhauster Series D and DN Differ

Despite the common purpose, these two series are not interchangeable. They were developed for different aerodynamic conditions, which is reflected in the design and operating parameters. They are often confused with VDN series forced draft fans, but the latter supply clean air to the furnace, while D and DN are designed specifically for smoke extraction.

Design Features

The DN series and D series smoke exhausters have differences starting with the impeller geometry. In D models, a wheel with forward-curved blades is used, which ensures compactness at high pressure. DN smoke exhausters have a different layout: their blades are curved backward, they have a more massive impeller, a reinforced housing made of carbon steel, and greater metal thickness (in mm). Additionally, the changed configuration of the scroll ensures flow stability and higher efficiency at high loads.

Pressure Level: Low/Medium (D) vs High (DN)

The main difference between these series manifests in the ability to overcome system resistance. D models work in the zone of low and medium pressure, which is sufficient for standard gas ducts without complex fittings. The DN smoke exhauster is designed for significantly higher loads when resistance is formed by long channels, cyclones, or heat exchangers. That is why DN smoke exhausters are often installed in complex technological schemes where draft stability is important regardless of the operating mode.

Air Flow Rate

The volume of gas flow also differs significantly. For D models, stable operation at moderate performance is characteristic, which is well suited for local boiler rooms. In the DN series, the emphasis is on large smoke flow rates while maintaining pressure. This is achieved due to a different blade profile and an increased impeller diameter in decimeters, which directly affects the unit's capabilities.

Complexity of Operating Conditions

The environment in which the equipment operates dictates requirements for units and materials. Formally, smoke exhauster series D and DN belong to medium pressure machines. But with identical dimensions, DN creates greater head and has higher efficiency in difficult sections. DN smoke exhausters have a rigid shaft and are designed for heavy modes with increased temperature, dust, and aggressive impurities. They require reinforced bearings, as well as units withstanding uneven loads. D models are less demanding on the environment and are better suited for conditions where the gas mixture composition is stable. D smoke exhausters are more often designed for "direct discharge" operation (short tract), while DN — for systems with a developed network of air ducts.

Where D Smoke Exhausters Are Used

The scope of application of D models is formed around classic boiler schemes. Such centrifugal smoke exhausters are often integrated into systems with short gas ducts and low aerodynamic resistance. They are used for boiler D, local furnaces, as well as installations with a predictable combustion mode. Due to simpler design, these models are well suited for objects where maintainability and stable performance without overloads are important.

Where DN Smoke Exhausters Are Used

The DN series is oriented towards other tasks. DN smoke exhausters are installed in large boiler rooms, thermal power plants, and industrial heat engineering complexes. They work with significant volumes of combustion products, often at high temperatures and variable loads. DN smoke exhausters are effective where the system includes filters, recuperators, or long chimneys.

How to Choose Between D and DN for Your Facility

Choosing a smoke exhauster variety always begins with analyzing the entire system, not just one parameter. Each point affects the final efficiency and resource of the equipment. In practice, it is advisable to immediately consider the layout of the entire smoke extraction route, since the type of smoke exhauster affects not only the draft but also the connection geometry, equipment placement, and further system maintenance.

Volume of Flue Gases

First of all, the actual volume of carbon monoxide smoke generated during boiler operation is determined. If the flow is stable and does not exceed average values, D models are sufficient. With large removal volumes, especially in peak load mode, it is better to prefer DN smoke exhausters capable of working without losing parameters.

Operating Pressure and System Resistance

The next stage of smoke exhauster selection is assessing gas duct resistance. The presence of turns, filters, or heat exchangers sharply increases losses. In such conditions, D series fans may be insufficient, while DN are designed specifically to overcome such resistance. Here, an important role is played not only by power but also by impeller aerodynamics.

Temperature Range

The temperature regime determines the choice of materials. Both series work with hot gases, but the specific inlet temperature affects the choice of housing steel and unit protection. Standardly, both D and DN are designed for gas flow temperatures up to +200°C... +250°C. If the temperature is higher, in both cases, special execution from heat-resistant steel (for example, 09G2S or stainless steel) is required. At high temperatures, the safety margin of the DN smoke exhauster structure is usually higher.

Is Heat Resistance or Explosion Protection Needed

For environments with high content of dust, resins, or aggressive impurities, standard D and DN models are not suitable. In such conditions, special execution corresponding to GOST (DSTU) standards regarding wear resistance and safety is chosen. If the temperature exceeds +250°C, heat-resistant steel is used. With gas ignition risk, explosion-proof execution from dissimilar metals is mandatory. This is critical for balanced air supply and stable removal of combustion products, guaranteeing the reliability of the entire system in extreme modes.

Popular Smoke Exhauster Selection Parameters (Examples of Requirement Formulation)

When forming technical specifications, the required capacity, permissible pressure, and impeller diameter are usually indicated. Separately, the motor type is fixed — most often asynchronous, rotation direction, and configuration of each nozzle. Also, the housing material, installation conditions, where the unit is installed, and the character of the air and gas mixture are specified.

Why Choose Smoke Exhausters from Manufacturer Ventilator.ua

The Ventilator.ua company offers a wide range of smoke exhausters of various types at affordable prices. We invite you to buy smoke exhausters with a guarantee from the manufacturer. The sale is accompanied by specialist consultation, a full package of documents for the device, and delivery across Ukraine.

Products of Kyiv Fan Plant

The Ventilator.ua catalog presents units manufactured by KVZ, developed for various heat engineering tasks. The model range covers options for standard and complex schemes, including solutions for boiler rooms and industrial facilities.

Certification

Every smoke exhauster released at KVZ undergoes control for compliance with technical norms. GOST certification confirms parameter stability and smoke exhauster compliance with declared characteristics.

Availability of Different Pressure Ranges (Low/Medium/High)

Solutions of different pressure classes presented in the smoke exhauster catalog from the Ventilator.ua online store allow selecting a modification for a specific task without compromise. Additional advantages of cooperation with us include consultation, logistics, and delivery across Ukraine.

Write a comment